Technical Data

| Feature | Detail |

|---|---|

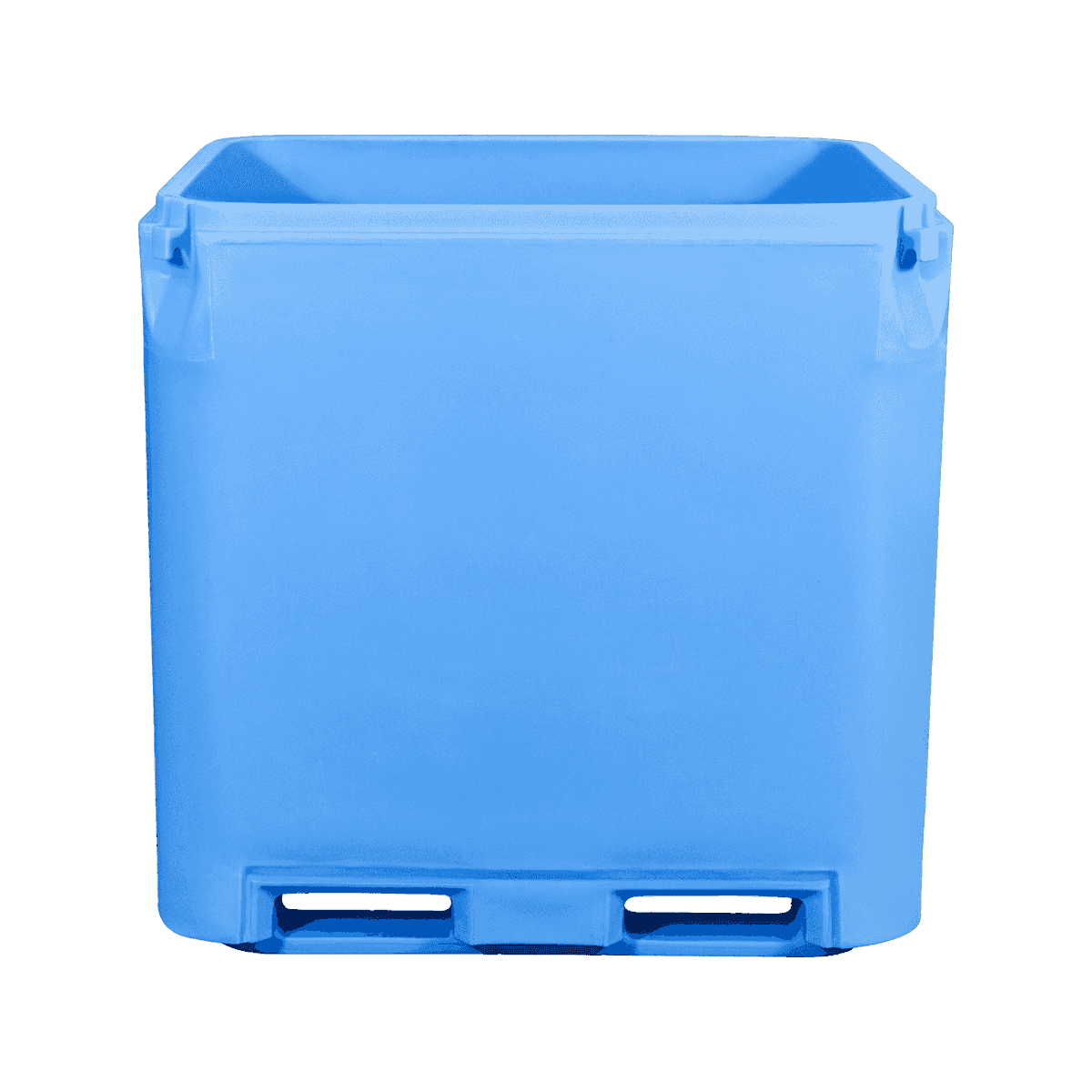

| Hygienic Design |

No Internal Seams or Crevices |

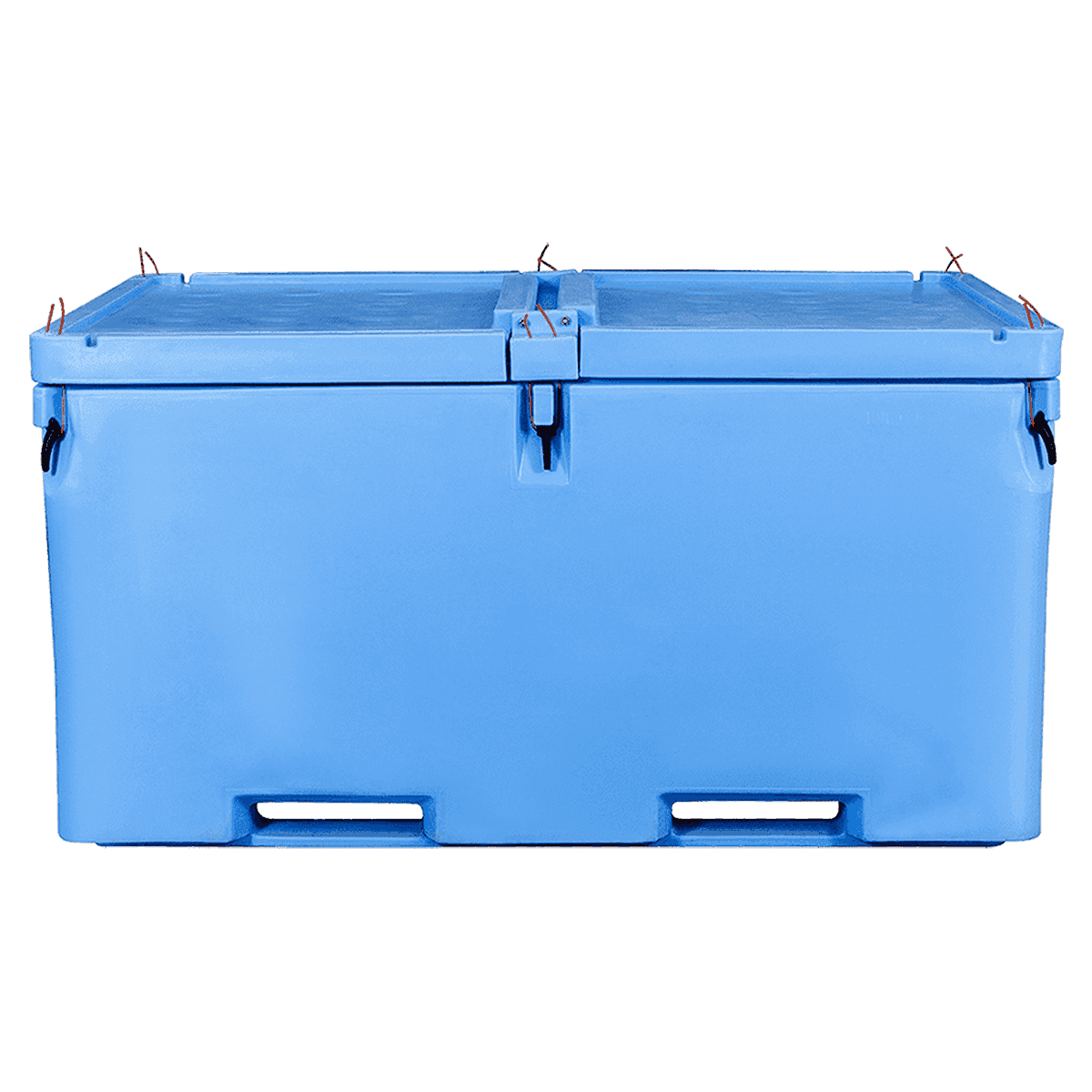

| Temperature Range |

Optimized for $\text{0°C}$ to $\text{4°C}$ Holding |

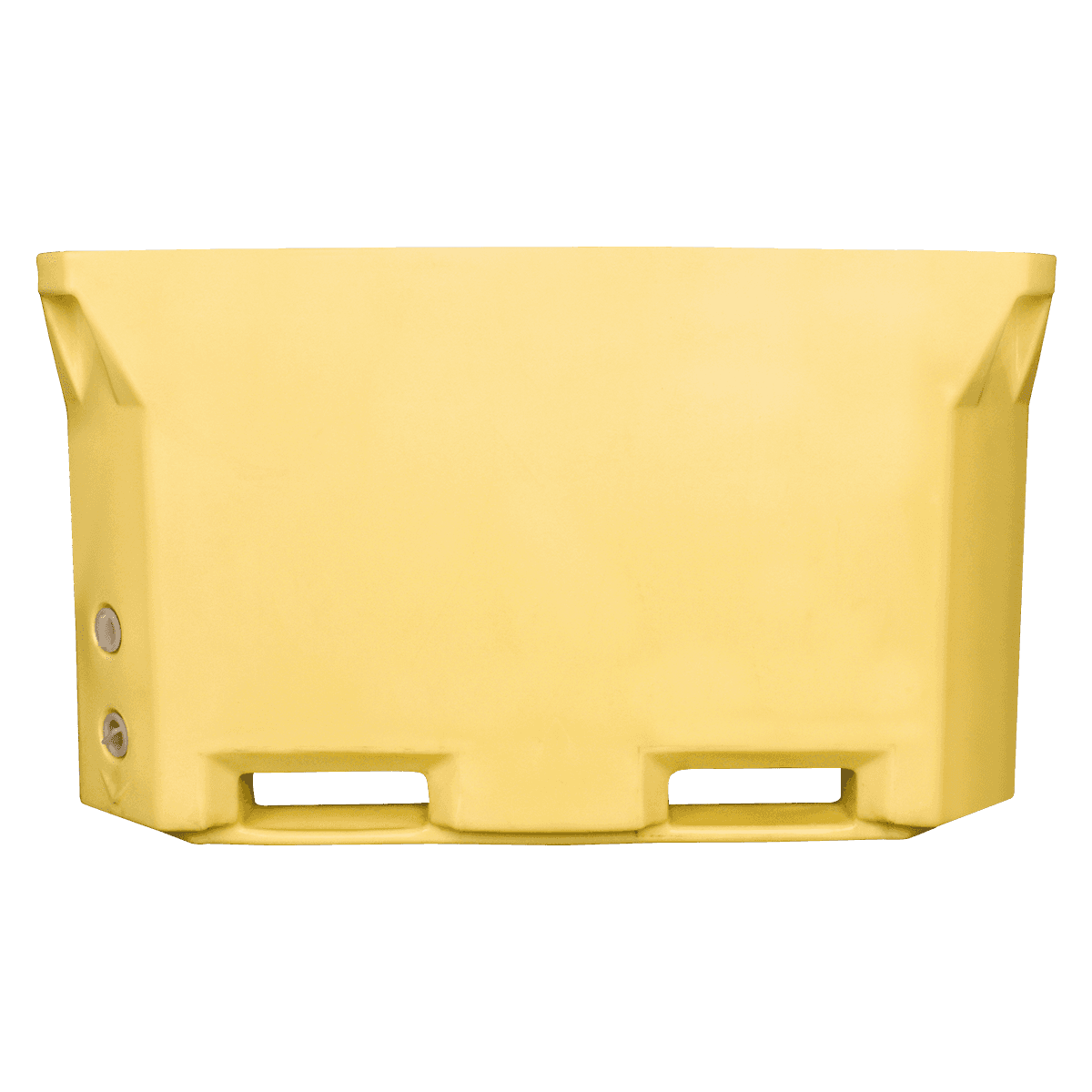

| Material |

Food-Grade, High-Density LLDPE |

| Handling |

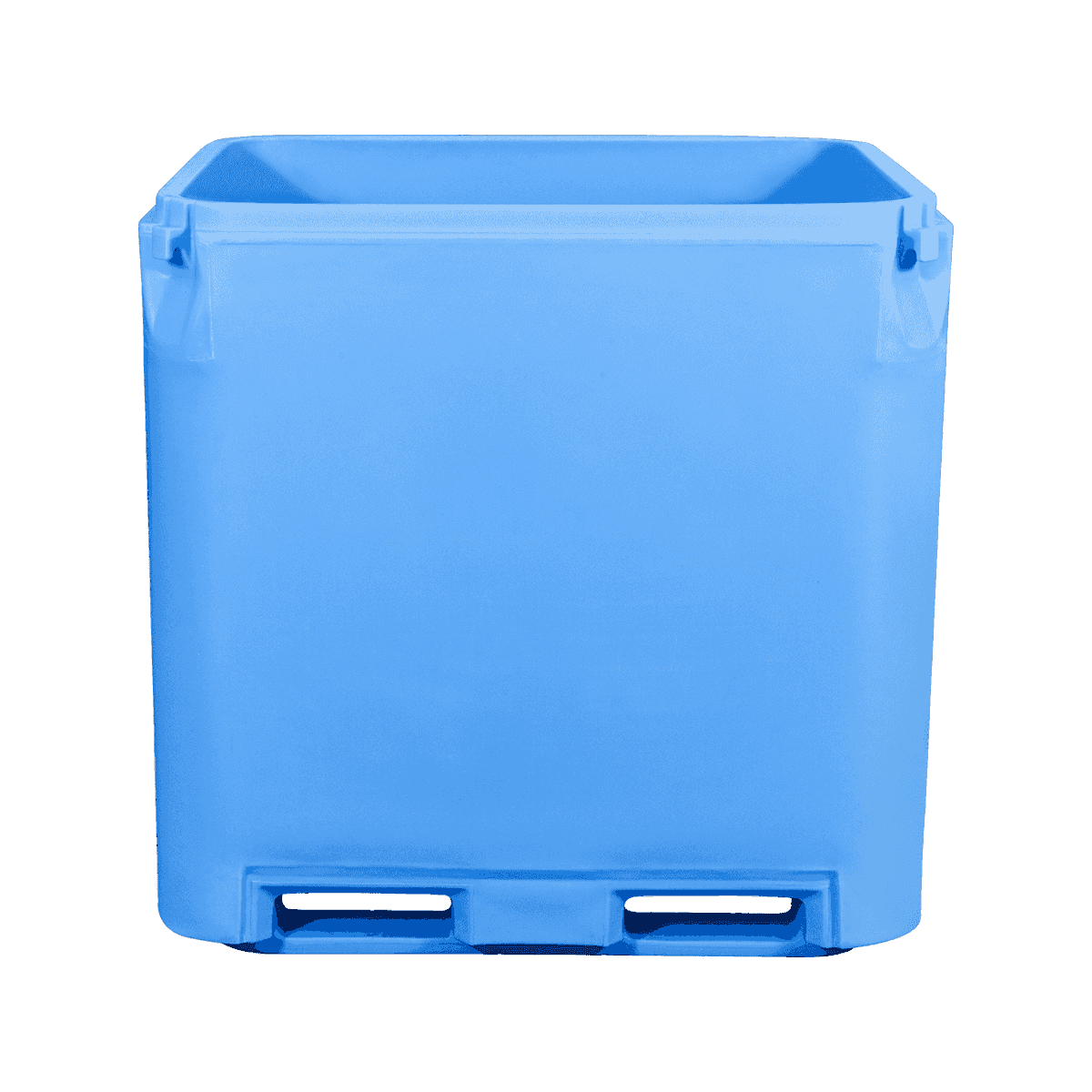

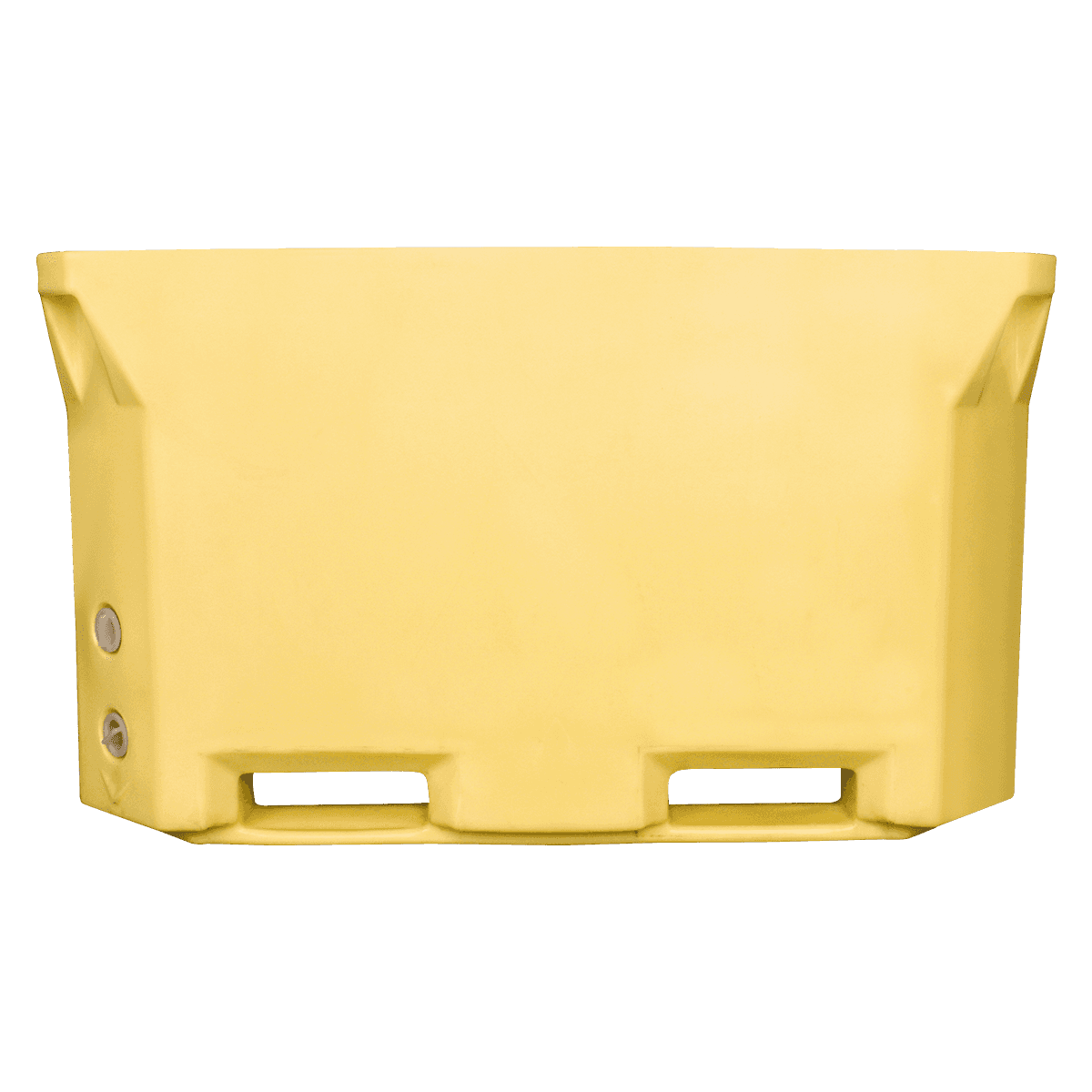

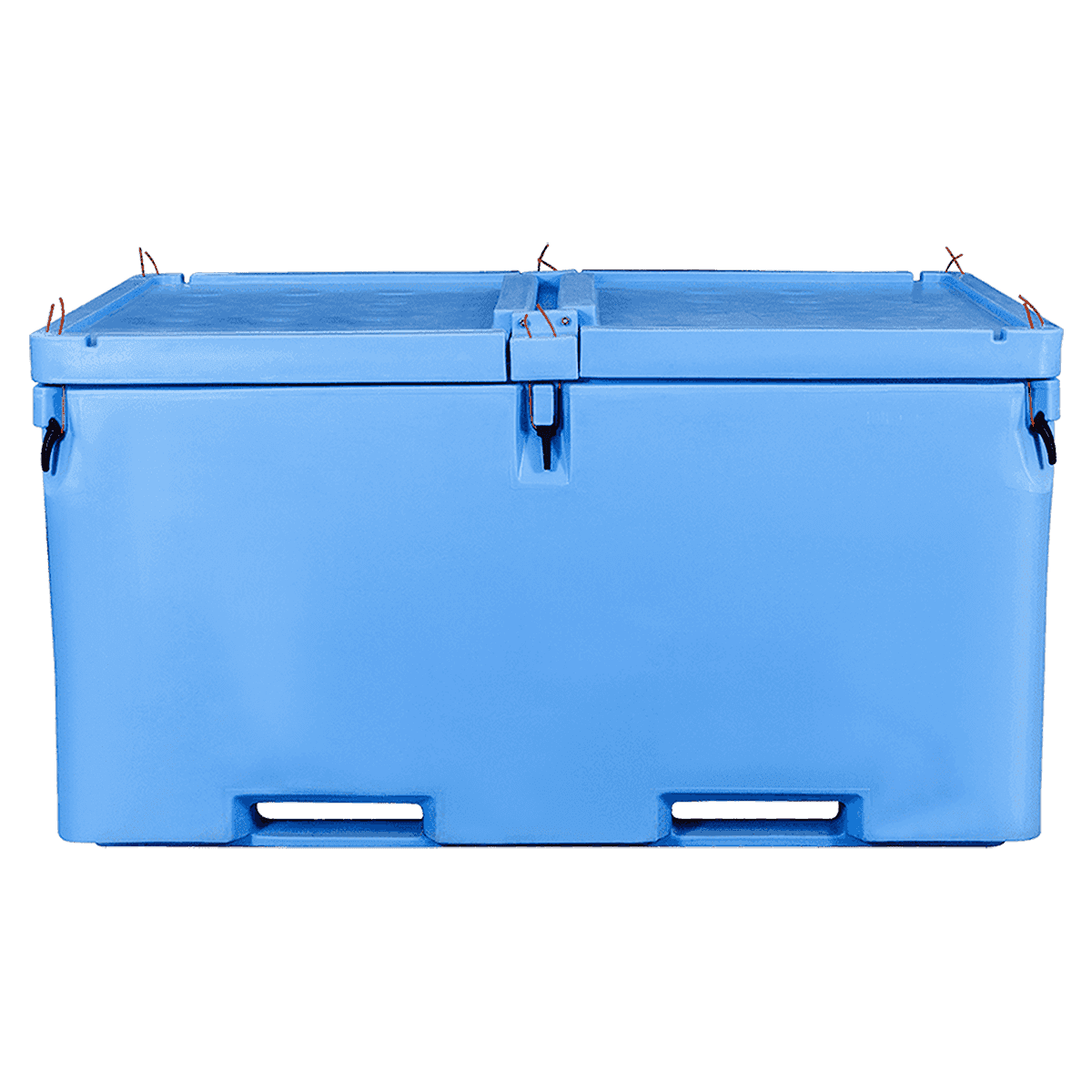

Integrated Pallet Base for Forklift/Jack Handling |

| Stackability |

Securely Interlocking for High Stacking |

| Moisture Management |

Optional Drain Plug for Meltwater/Blood Management |

Primary Use Cases

-

Poultry Processing Plants: Rapid chilling of whole birds or cut-up parts immediately after packaging.

-

In-Plant Transport: Moving chilled poultry products between different processing zones.

-

Distribution and Export: Maintaining the cold chain during regional or international transport.

-

Raw Material Holding: Temporary storage of raw ingredients or byproducts requiring insulation.

Why Choose Our Containers?

-

Critical Temperature Control: Our thick PU foam insulation ensures consistent temperature retention, minimizing the risk associated with high-risk poultry products.

-

Superior Cleanability: The smooth, seamless interior surfaces prevent accumulation of pathogens, supporting rigorous sanitation schedules.

-

Chemical Resistance: Robust construction stands up to strong detergents and disinfectants used routinely in poultry facility washdowns.

-

Durability: Designed for constant handling and high stacking, providing long-term reliability in a demanding, high-volume industry.

English

English Español

Español عربى

عربى 中文简体

中文简体

-2.png)