Product Category:

- All products

- Food use insulated plastic containers

- Seafood Industrial Use Plastic Containers

- Meat/Poultry Industrial Use Plastic Containers

- Logistics And Cold-Chain Containers

- Workshop And Warehouse Use Cold-Chain Containers

- Long Distance Live Fish Transportation Containers

- Live Seafood Farming & Transportation Tanks

- Outdoor leisure use cooler box

- Ice Cooler Container

- Ice Cooler Box

- Boats and docks use containers

- Vessels And Dock Use Ice Box

- Extra large size boats use containers

Product:

We Can Save Cost And Create Value For You

Our Products

Insulated Pallet Containers Manufacturers

-

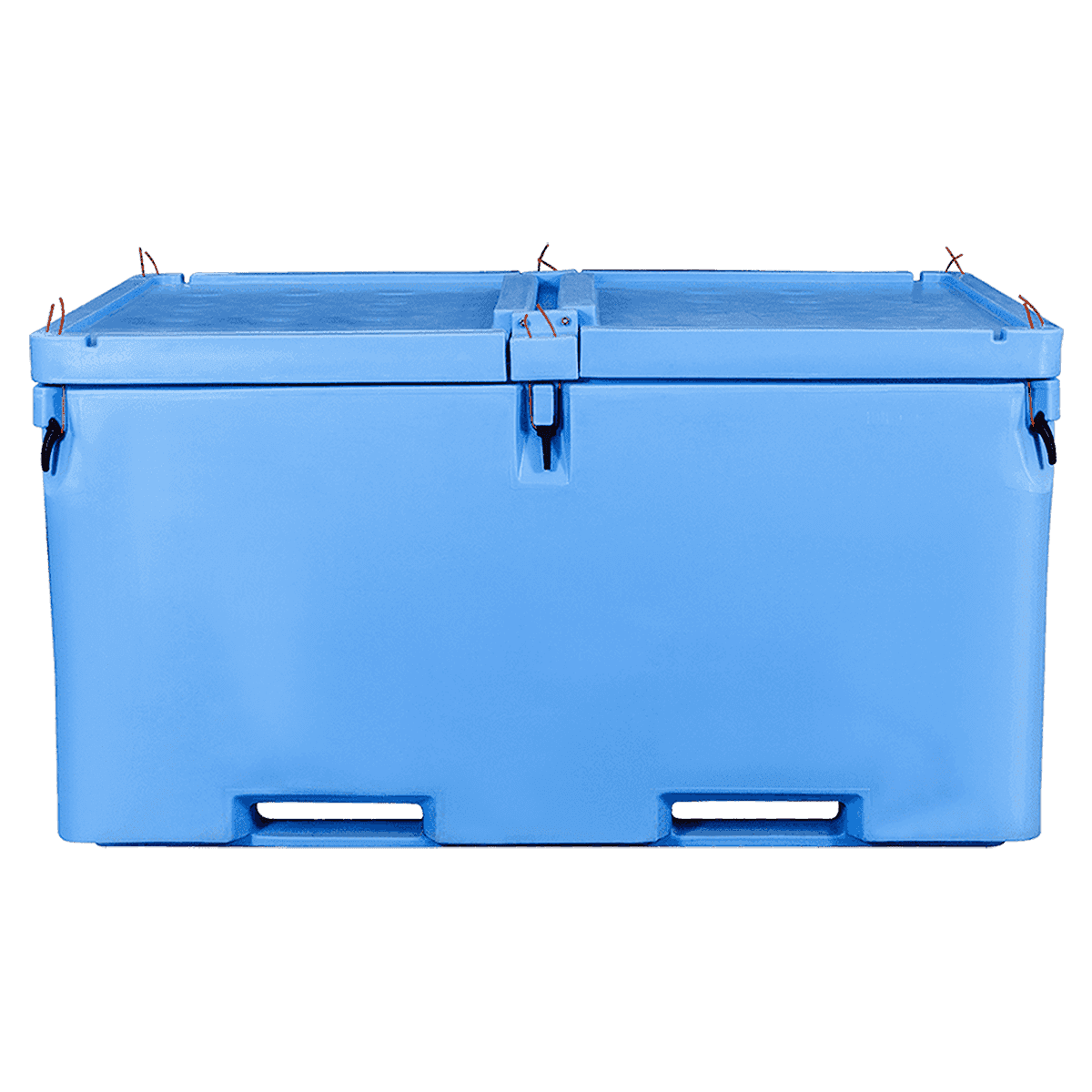

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

AF-1700L

-

.png?imageView2/2/format/jp2)

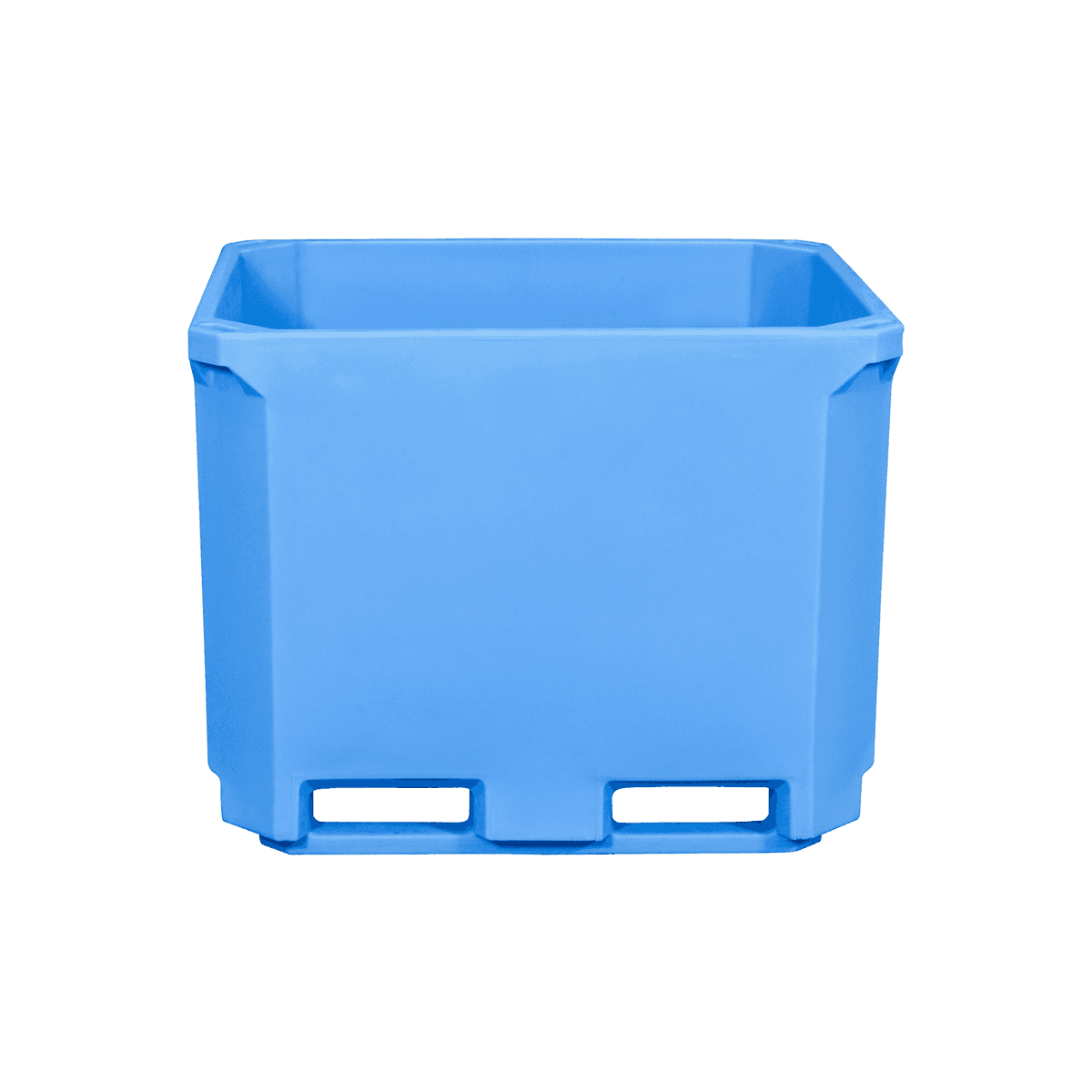

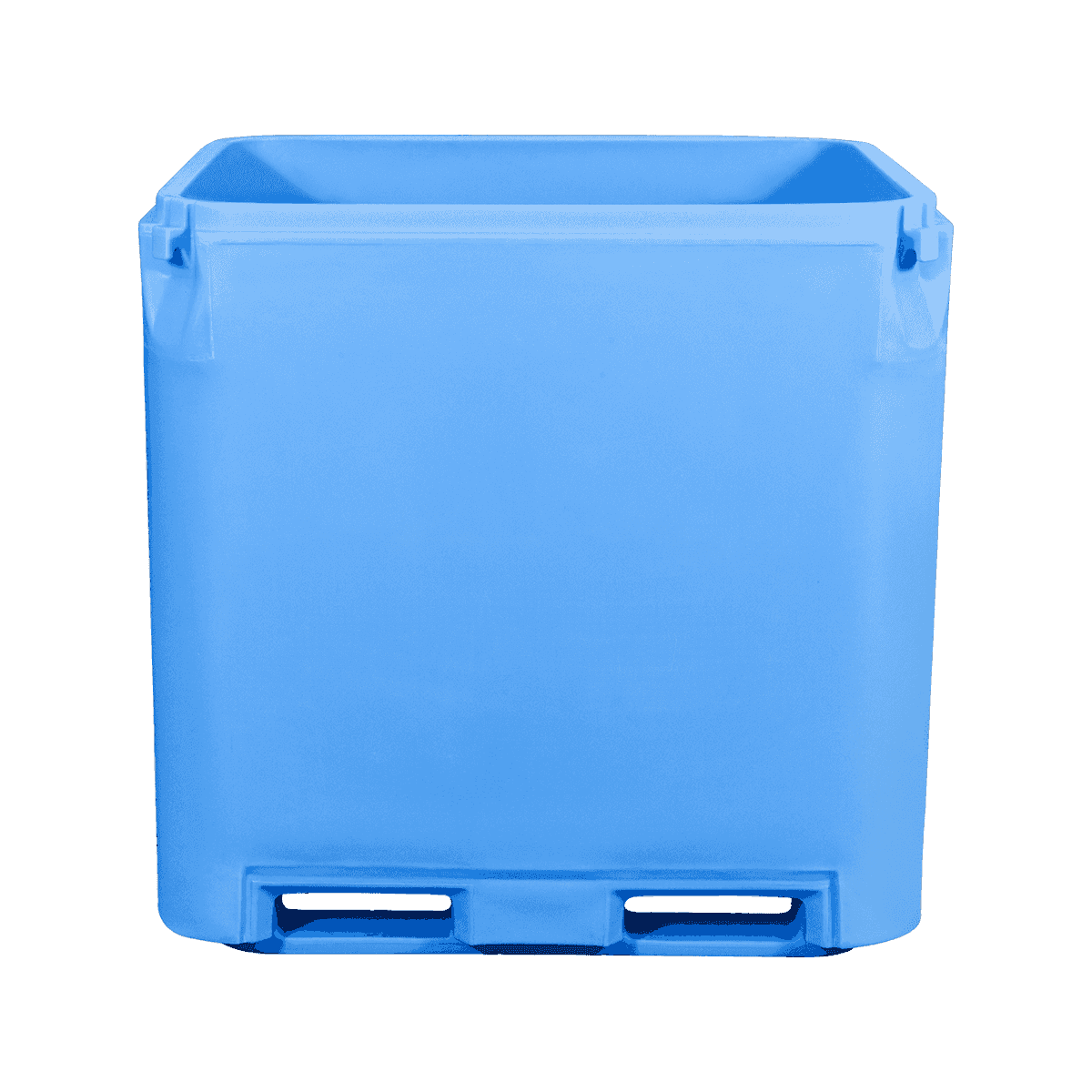

AF-340L Seafood Bins Seafood Industrial Use Plastic Containers

AF-340L

-

AF-380L Insulated Fish Tubs Seafood Industrial Use Plastic Containers

AF-380L

-

AF-460L Food Grade Fish Boxes Seafood Industrial Use Plastic Containers

AF-460L

-

.png?imageView2/2/format/jp2)

AF-660L Rotomolded Cooler Seafood Industrial Use Plastic Containers

AF-660L

-

.png?imageView2/2/format/jp2)

AF-800L Seafood Industrial Use Plastic Containers

AF-800L

-

AF-1000L Insulated Fish Totes Seafood Industrial Use Plastic Containers

AF-1000L

-

F-300L Insulated Seafood Industrial Use Plastic Containers

F-300L

-

F-660L Insulated Fish Containers Seafood Industrial Use Plastic Containers

F-660L

-

F-1000L Insulated Fish Tanks Seafood Industrial Use Plastic Containers

F-1000L

-

-2.png?imageView2/2/format/jp2)

CF-780L Insulated Bulk Containers Seafood Industrial Use Plastic Containers

CF-780L

-

CF-1000L Plastic Fish Totes Seafood Industrial Use Plastic Containers

CF-1000L

since 2008

Ningbo Wanma Plastics Co.,Ltd.

Ningbo Wanma Plastics Co., Ltd is professional China Insulated Seafood Containers Manufacturers and OEM Seafood Industrial Use Plastic Containers Company, we offer wholesale Seafood Industrial Use Plastic Containers for sale at factory price.

Established in 2008, our company is an enterprise led by a young and creative team. We have been focusing on the design, manufacture and research and development of Seafood Industrial Use Plastic Containers products for more than ten years. We have excellent and unique technology in the field of one-piece seamless molding of double-wall containers, such as PU filling for thermal insulation barrels and sandwich structure products. All of our Seafood Industrial Use Plastic Containers products comply with national food hygiene standards and are widely used to fully meet the storage turnover needs of various usage scenarios.

We welcome all inquiries from all over the world with warm greetings. High quality is our cornerstone, innovation is our blood. We believe we can provide better Seafood Industrial Use Plastic Containers products with our professional team and advanced equipment. We frankly look forward to working with you in the future.

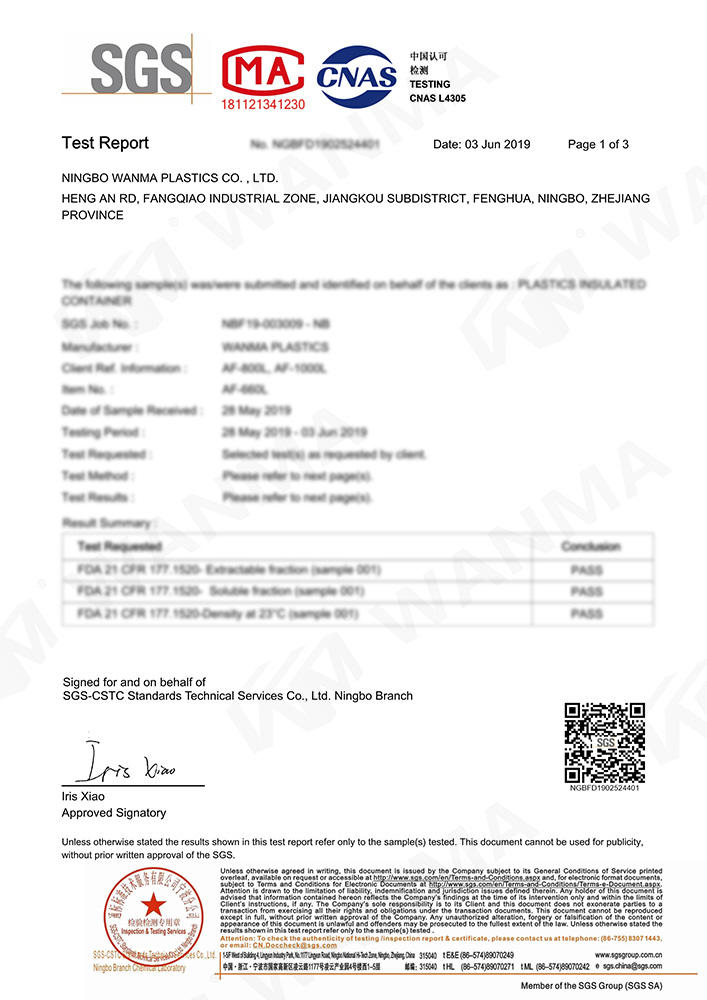

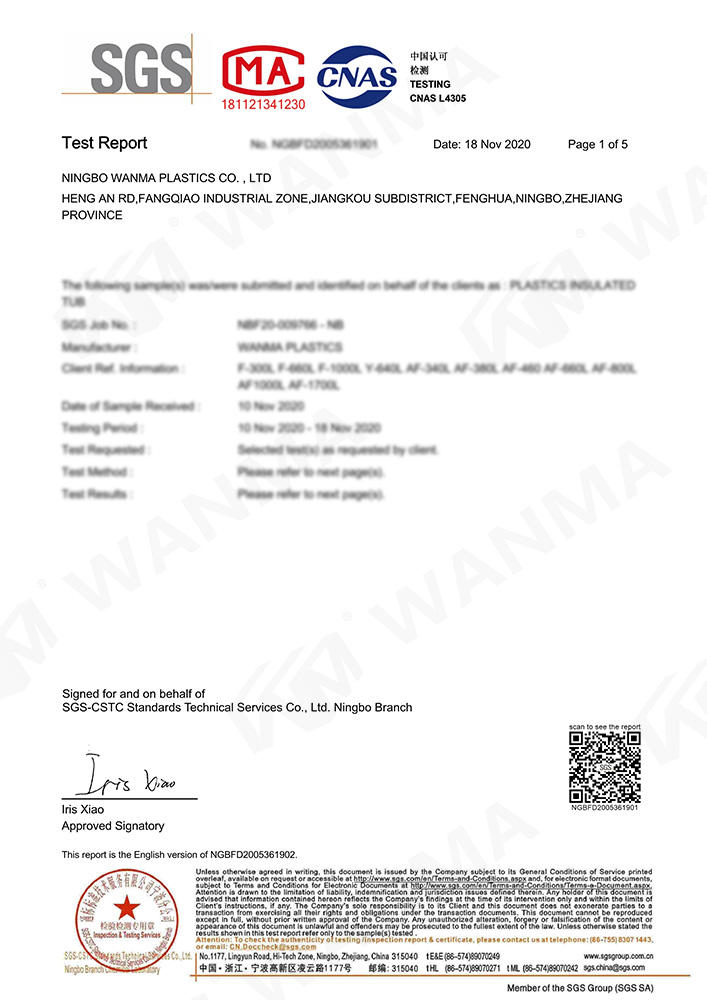

Quality and Certifications

Being an ISO-9001 certified manufacturer, we maintain manufacturing quality. Our products are made to European and international standards, and successfully pass the certification testing of CE, SGS and TUV on a regular basis.

Eu Report

FDA Report

Food Grade Report

ISO

ISO9001

Seafood Industrial Use Plastic Containers Industry Knowledge Extension

1.Why Are Insulated Pallet Containers Essential for Modern Seafood Storage and Transport?

The global seafood industry operates on razor-thin margins when it comes to preserving product quality. From harvest to retail, temperature fluctuations of even a few degrees can lead to spoilage, bacterial growth, or texture degradation, resulting in significant financial losses. Insulated pallet containers have become indispensable in addressing these challenges, offering a robust solution to maintain consistent cold chain integrity. These containers leverage advanced insulation materials like polyurethane (PU) foam and double-wall sandwich structures to create a thermal barrier, effectively slowing heat transfer and maintaining stable internal temperatures for up to 48 hours or more, depending on external conditions.

At Ningbo Wanma Plastics Co., Ltd., innovation in thermal insulation is at the core of our design philosophy. Our insulated fish tubs are engineered using proprietary one-piece seamless molding technology, which eliminates joints and seams that traditionally weaken structural integrity and create thermal leakage points. This seamless design ensures uniform temperature distribution, critical for preserving delicate seafood such as salmon, tuna, and shellfish. For example, our containers can maintain temperatures between 0°C to 4°C for fresh fish or -18°C for frozen products, meeting the stringent requirements of international seafood exporters.

Wanma’s containers comply with global food safety standards, including FDA and EU regulations, thanks to their food-grade high-density polyethylene (HDPE) construction. This material is not only resistant to saltwater corrosion and UV degradation but also easy to sanitize, reducing cross-contamination risks. By partnering with Ningbo Wanma Plastics, businesses gain access to containers that extend shelf life, minimize waste, and reduce reliance on single-use packaging—a growing concern in sustainability-focused markets.

2.How to Choose the Right Insulated Pallet Container for Your Cold Chain Needs?

Selecting the ideal insulated pallet container requires a deep understanding of both operational demands and environmental variables. Key factors include insulation performance, durability, regulatory compliance, and adaptability to logistics workflows. Here’s a breakdown of critical considerations:

Thermal Retention Capabilities:

Containers with PU foam-filled walls or vacuum-insulated panels (VIPs) offer superior thermal efficiency. Wanma’s insulated fish tubs, for instance, utilize a dual-layer design with 40–60 mm PU foam insulation, achieving a thermal conductivity rate as low as 0.022 W/m·K. This ensures optimal temperature retention even in tropical climates or during extended transit.

Material and Structural Resilience:

High-quality HDPE or polypropylene ensures resistance to impact, chemicals, and extreme temperatures. Ningbo Wanma Plastics Co., Ltd. reinforces its containers with ribbed exteriors and reinforced corners, enabling them to withstand stacking heights of up to 5 layers without deformation—a crucial feature for high-volume seafood exporters.

Ergonomic Design and Compatibility:

Containers must integrate seamlessly into existing supply chains. Wanma’s designs include features like forklift pockets, stackable lids, and compatibility with automated warehouse systems. For example, our insulated fish tubs are available in modular sizes (20L to 1,000L) to accommodate diverse catch volumes, from small-batch artisanal fisheries to industrial trawlers.

Sustainability and Cost Efficiency:

Reusable containers significantly reduce long-term costs compared to disposable alternatives. Ningbo Wanma’s products are built for 10+ years of service, with replaceable parts to extend lifespan. Additionally, their lightweight design cuts fuel consumption during transport, aligning with carbon reduction goals.

As a leader in seafood container manufacturing, Ningbo Wanma Plastics Co., Ltd. offers tailored consultations to help clients match their cold chain requirements with the right product. Whether you need containers optimized for ice-packed lobster transport or cryogenic freezing, our team provides data-driven solutions backed by a decade of R&D expertise.

3.What Sets Ningbo Wanma Plastics Apart in Insulated Container Manufacturing?

Since its founding in 2008, Ningbo Wanma Plastics Co., Ltd. has carved a niche as a trailblazer in hygienic, high-performance plastic containers for the seafood industry. What differentiates Wanma is its fusion of youthful innovation and engineering precision. Our team—comprising chemists, designers, and logistics experts—continuously pushes boundaries in thermal insulation technology.

A standout innovation is our patented one-piece seamless molding process. Traditional containers are welded or bolted, creating seams that harbor bacteria and compromise insulation. Wanma’s method produces insulated fish tubs in a single mold, resulting in leakproof, unibody structures that excel in both hygiene and thermal efficiency. This technology has been validated in extreme conditions, such as 72-hour transoceanic shipments, where Wanma containers maintained temperature stability with less than 1°C deviation.

Our commitment to customization sets us apart. Recognizing that no two seafood operations are identical, we offer OEM services to tailor container dimensions, insulation thickness, and accessory integrations (e.g., drainage plugs, RFID tracking mounts). For a Japanese client, we developed a compact 30L insulated tub with quick-release latches for rapid unloading aboard fishing vessels—reducing labor time by 30%.

Sustainability is another pillar of Wanma’s ethos. Our containers are 100% recyclable, and we’ve implemented a closed-loop production system to repurpose manufacturing scrap into raw materials. This circular approach, combined with energy-efficient molding machines, minimizes our carbon footprint while delivering cost savings to clients.

Ningbo Wanma Plastics Co., Ltd. invests heavily in quality assurance. Every batch of insulated fish tubs undergoes rigorous testing, including thermal shock trials, load-bearing assessments, and microbial resistance checks. Our certifications—from ISO 9001 to BRCGS—reflect our unwavering dedication to global standards.

English

English Español

Español عربى

عربى 中文简体

中文简体