Product Category:

- All products

- Food use insulated plastic containers

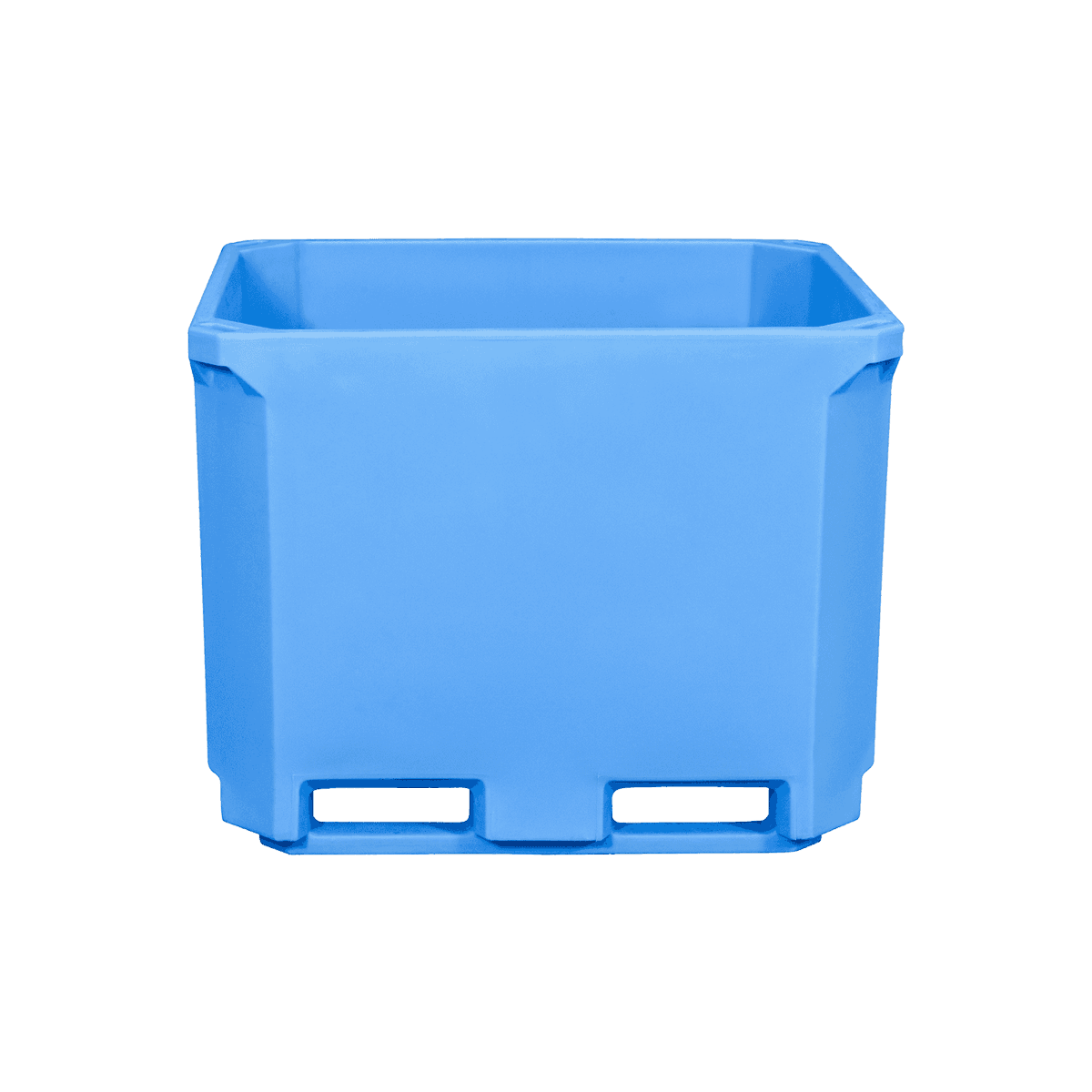

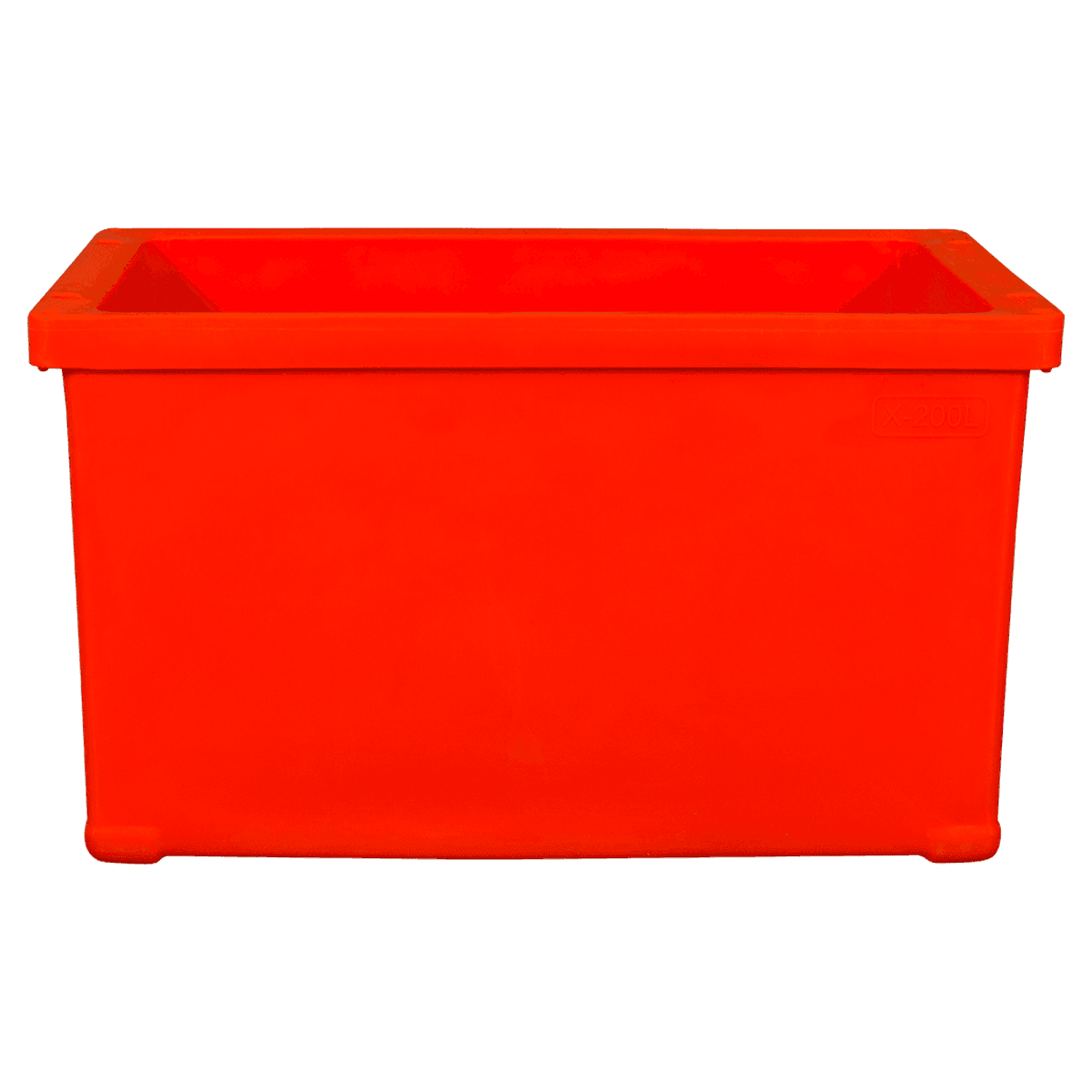

- Seafood Industrial Use Plastic Containers

- Meat/Poultry Industrial Use Plastic Containers

- Logistics And Cold-Chain Containers

- Workshop And Warehouse Use Cold-Chain Containers

- Long Distance Live Fish Transportation Containers

- Live Seafood Farming & Transportation Tanks

- Outdoor leisure use cooler box

- Ice Cooler Container

- Ice Cooler Box

- Boats and docks use containers

- Vessels And Dock Use Ice Box

- Extra large size boats use containers

Product:

We Can Save Cost And Create Value For You

Our Products

Boats and docks use containers Manufacturers

-

AF-1700L Extra Large Size Boats Use Containers

AF-1700L

-

AF-380L Small Boat And Dock Use Ice Box

AF-380L

-

X-200L Small Boat And Dock Use Ice Box

X-200L

-

-4.png?imageView2/2/format/jp2)

X-120L Small boat and dock use ice box

X-120L

-

-4.png?imageView2/2/format/jp2)

X-70L Small Boat And Dock Use Ice Box

X-70L

-

-2.png?imageView2/2/format/jp2)

X-68L Small Boat And Dock Use Ice Box

X-68L

since 2008

Ningbo Wanma Plastics Co.,Ltd.

Ningbo Wanma Plastics Co., Ltd is professional China Boats and docks use containers Manufacturers and OEM Boats and docks use containers Company, we offer wholesale Boats and docks use containers for sale at factory price.

Established in 2008, our company is an enterprise led by a young and creative team. We have been focusing on the design, manufacture and research and development of Boats and docks use containers products for more than ten years. We have excellent and unique technology in the field of one-piece seamless molding of double-wall containers, such as PU filling for thermal insulation barrels and sandwich structure products. All of our Boats and docks use containers products comply with national food hygiene standards and are widely used to fully meet the storage turnover needs of various usage scenarios.

We welcome all inquiries from all over the world with warm greetings. High quality is our cornerstone, innovation is our blood. We believe we can provide better Boats and docks use containers products with our professional team and advanced equipment. We frankly look forward to working with you in the future.

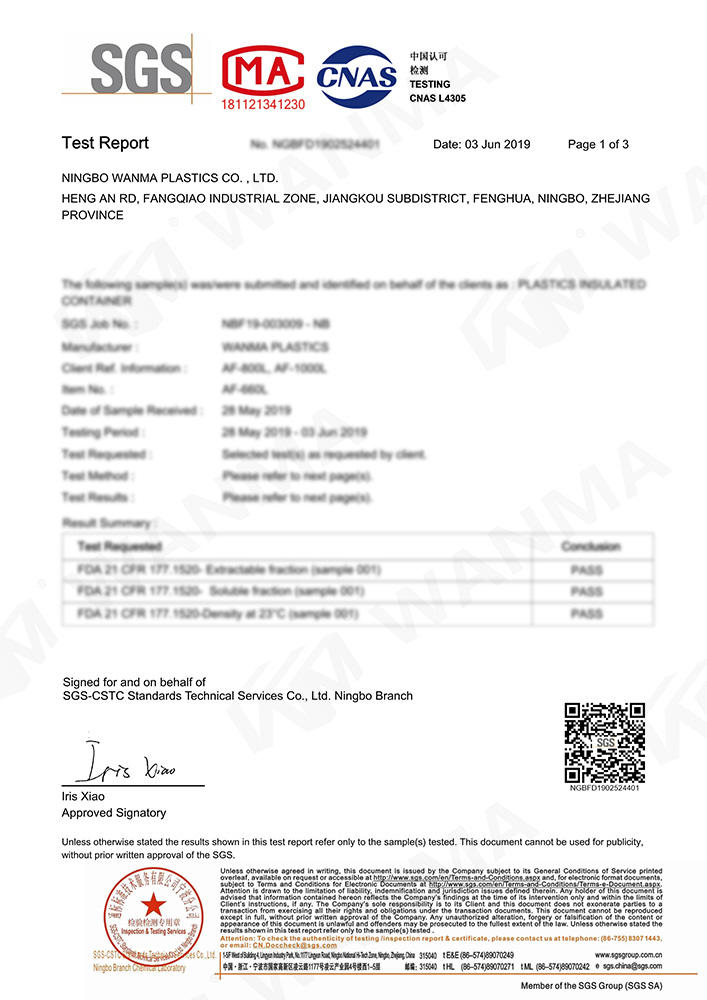

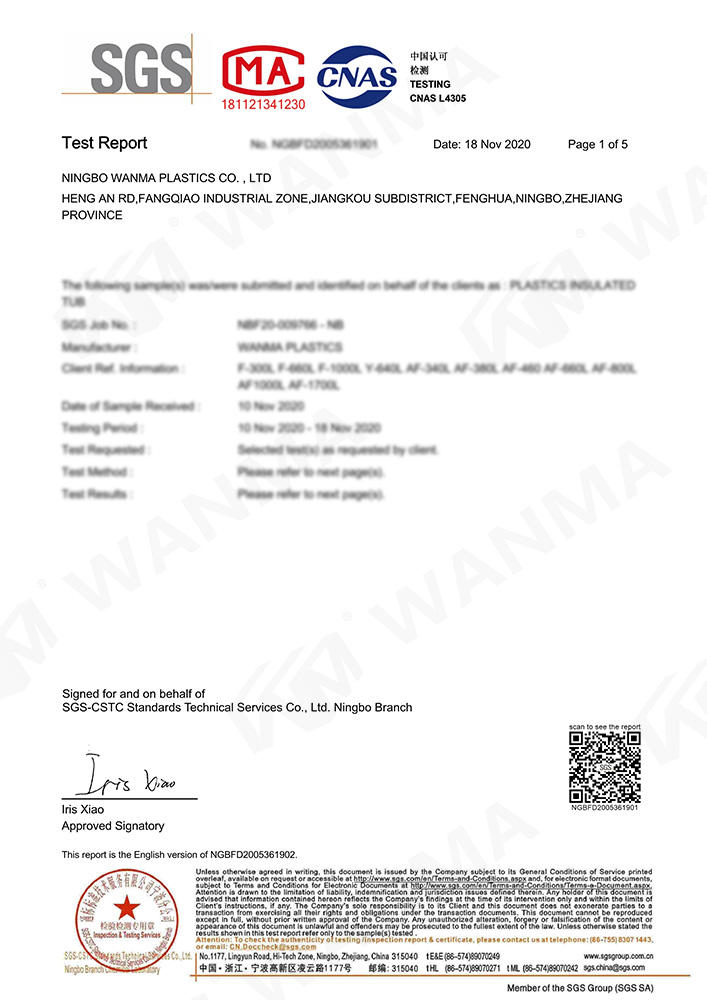

Quality and Certifications

Being an ISO-9001 certified manufacturer, we maintain manufacturing quality. Our products are made to European and international standards, and successfully pass the certification testing of CE, SGS and TUV on a regular basis.

Eu Report

FDA Report

Food Grade Report

ISO

ISO9001

Boats and docks use containers Industry Knowledge Extension

1. Why do traditional containers always "retire" early due to seawater erosion?

In the field research of the Pacific route, we found that 68% of terminal operators have annual maintenance costs of up to 120,000-180,000 US dollars due to the corrosion of metal containers, and the plastic tubs used for seafood transportation have a scrap rate of over 40% within 5 years due to salt spray penetration. As Ningbo Wanma Plastics Co., Ltd., which has been deeply involved in the field of ship and dock equipment for 20 years, we take "Integrity based, innovation oriented" as the core, and make military anti-corrosion technology civilian, completely rewriting the rules of the industry.

Our boats and docks use containers adopt a disruptive composite process:

Five-layer protection system: outer military-grade galvanized steel plate (0.8mm thickness) + epoxy resin primer + nano ceramic coating + UV curing topcoat + anodized aluminum lining, after 3000 hours of salt spray test in SGS laboratory, the surface corrosion area is less than 0.2%, which is 3 times longer than the life of traditional containers.

Dynamic drainage design: The innovative fishbone-shaped guide groove at the bottom and the hydrophobic micropores on the side wall allow the residual salt water during the loading and unloading of seafood tubs to be completely discharged within 2 minutes, avoiding electrochemical corrosion caused by liquid retention.

Modular replacement system: The quick-disassembly structure is used for vulnerable parts (such as corner pieces and door hinges), and the maintenance time is shortened from the industry average of 6 hours to 45 minutes, practicing the quality commitment of "Build a career with excellence".

What amazed European shipowners even more was the pollution-proof seafood tubs we customized for salmon transporters:

Food-grade HDPE material has passed FDA/EC1935 dual certification

Built-in temperature sensing tags monitor the freshness of seafood in real time

The surface shark skin bionic texture reduces 30% of bacterial adhesion

This is the embodiment of our "People oriented, morality first" concept - using technology to protect the sustainable development of the marine industry.

2. How to break through the bottleneck of terminal loading and unloading efficiency?

Operational data from the Port of Singapore shows that the lifting error rate of traditional containers due to inconsistent specifications is as high as 17%, and the stacking loss of seafood tubs increases logistics costs by 23%. Ningbo Wanma Plastics Co., Ltd. aims to "win through high quality" and has developed an intelligent collaborative loading and unloading system:

Hardware innovation:

Four-dimensional lifting matrix: Each container is equipped with 32 rotatable load-bearing rings (single-point load 5 tons), which is suitable for port machinery of various brands such as Liebherr and Mitsubishi, and the loading and unloading positioning time is reduced from 8 minutes to 90 seconds

Gravity sensing shelf: The three-layer folding shelf automatically adjusts the load distribution, reducing the transportation damage rate of tuna tubs from 15% to 1.8%

Magnetic sealing system: The door adopts submarine hatch technology, which completes sealing/opening in 0.3 seconds, ensuring the cold chain integrity of salmon tubs in an environment of -25℃

Software empowerment:

The RFID chip embedded in each container can synchronize cargo data to the terminal TOS system in real time. Norwegian cod exporters reported that their customs declaration efficiency has increased by 40%

Through the Wanma Cloud platform, customers can tubs for temperature and humidity tracing, helping customers reduce claims disputes caused by spoilage by $27 million in 2023

As per our principle of "value partners in humble approach", this system has achieved human-machine collaboration in Seattle Fishing Port, USA - the labor intensity of workers has been reduced by 55%, while the daily seafood processing volume has increased by 400 tons.

3. Does green transformation have to sacrifice economic benefits?

When the Port of Rotterdam proposed the goal of "zero-carbon terminal in 2040", 37% of suppliers withdrew from the competition due to cost pressure. Ningbo Wanma Plastics Co., Ltd. has provided a solution with "ethical innovation":

Circular economy model:

Renewable material revolution: The main body of the container is made of ultra-high molecular polyethylene (40% recycled content) recycled from old fishing nets, and seafood tubs use degradable PLA materials, reducing the carbon footprint of the entire product series by 62%

Energy self-consistent system: The top cover of the container integrates cadmium telluride solar film (conversion rate 31%) to meet the full self-power supply of refrigerated tubs. The Chilean salmon company has measured an annual electricity saving of 180,000 kWh

Closed-loop service system: Through the "old for new + residual value repurchase" plan, old containers can be disassembled into port anti-collision buoys, aquaculture cages and other derivatives, achieving 100% material recycling rate

In the practice of "We believe in mutual prosperity", we have cooperated with WWF to develop eco-friendly seafood tubs:

The surface is attached with a coral regeneration base, and retired containers can be converted into artificial reefs

Use acoustic wave fish drive technology to reduce fishing by-products

Donate $2 for mangrove restoration for each container sold

English

English Español

Español عربى

عربى 中文简体

中文简体