Product Category:

- All products

- Food use insulated plastic containers

- Seafood Industrial Use Plastic Containers

- Meat/Poultry Industrial Use Plastic Containers

- Logistics And Cold-Chain Containers

- Workshop And Warehouse Use Cold-Chain Containers

- Long Distance Live Fish Transportation Containers

- Live Seafood Farming & Transportation Tanks

- Outdoor leisure use cooler box

- Ice Cooler Container

- Ice Cooler Box

- Boats and docks use containers

- Vessels And Dock Use Ice Box

- Extra large size boats use containers

Product:

We Can Save Cost And Create Value For You

Our Products

Ice Cooler Container Manufacturers

-

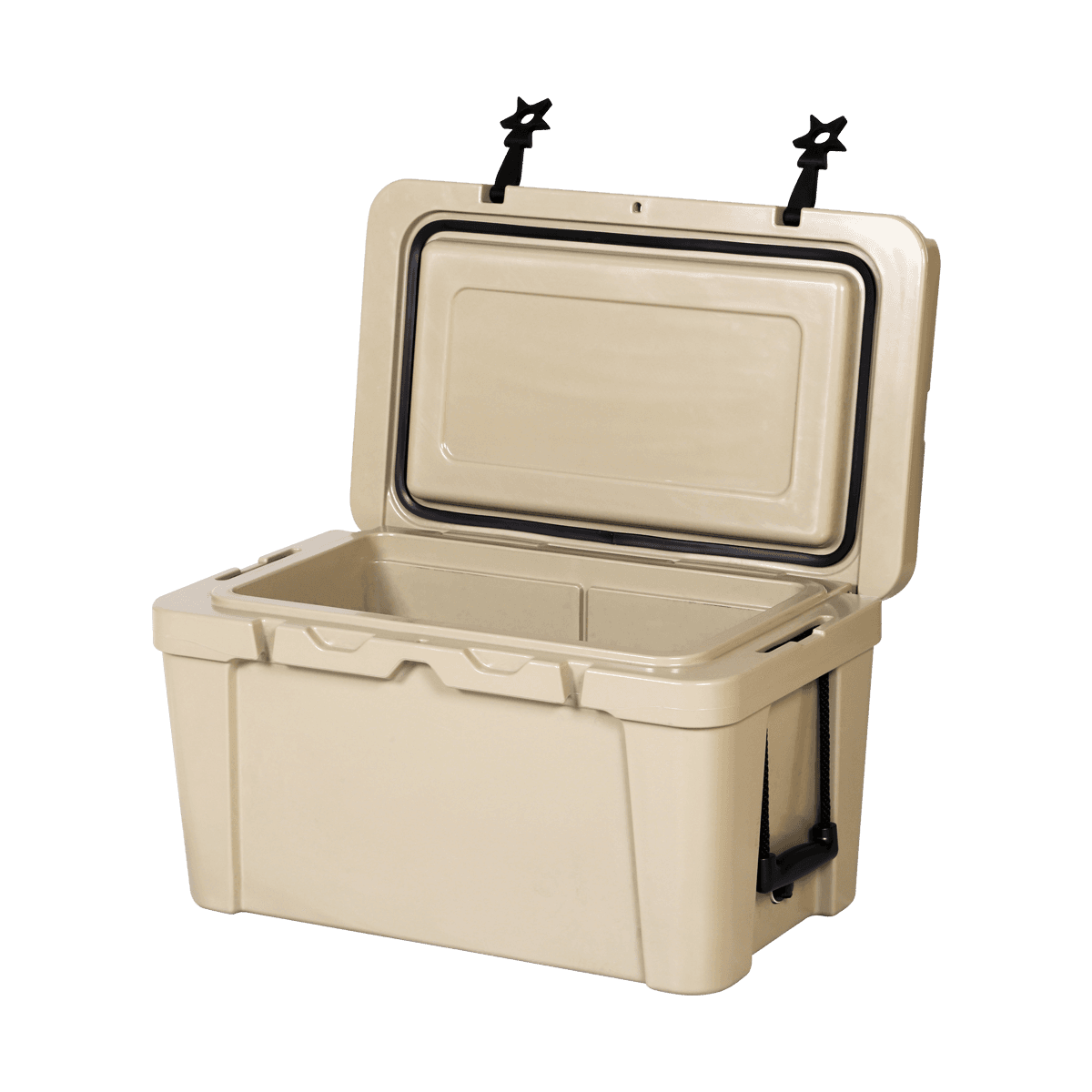

K-25L Portable Cooler Outdoor Leisure Use Cooler Box

K-25L

-

K-45L Rotomolded Insulation Ice Cooler for Outdoor Camping Fishing Hunting BBQs

K-45L

-

K-65L Outdoor Leisure Use Insulated Cooler Ice Box

K-65L

since 2008

Ningbo Wanma Plastics Co.,Ltd.

Ningbo Wanma Plastics Co., Ltd is professional China Ice Cooler Container Manufacturers and OEM Ice Cooler Container Company, we offer wholesale Ice Cooler Container for sale at factory price.

Established in 2008, our company is an enterprise led by a young and creative team. We have been focusing on the design, manufacture and research and development of Ice Cooler Container products for more than ten years. We have excellent and unique technology in the field of one-piece seamless molding of double-wall containers, such as PU filling for thermal insulation barrels and sandwich structure products. All of our Ice Cooler Container products comply with national food hygiene standards and are widely used to fully meet the storage turnover needs of various usage scenarios.

We welcome all inquiries from all over the world with warm greetings. High quality is our cornerstone, innovation is our blood. We believe we can provide better Ice Cooler Container products with our professional team and advanced equipment. We frankly look forward to working with you in the future.

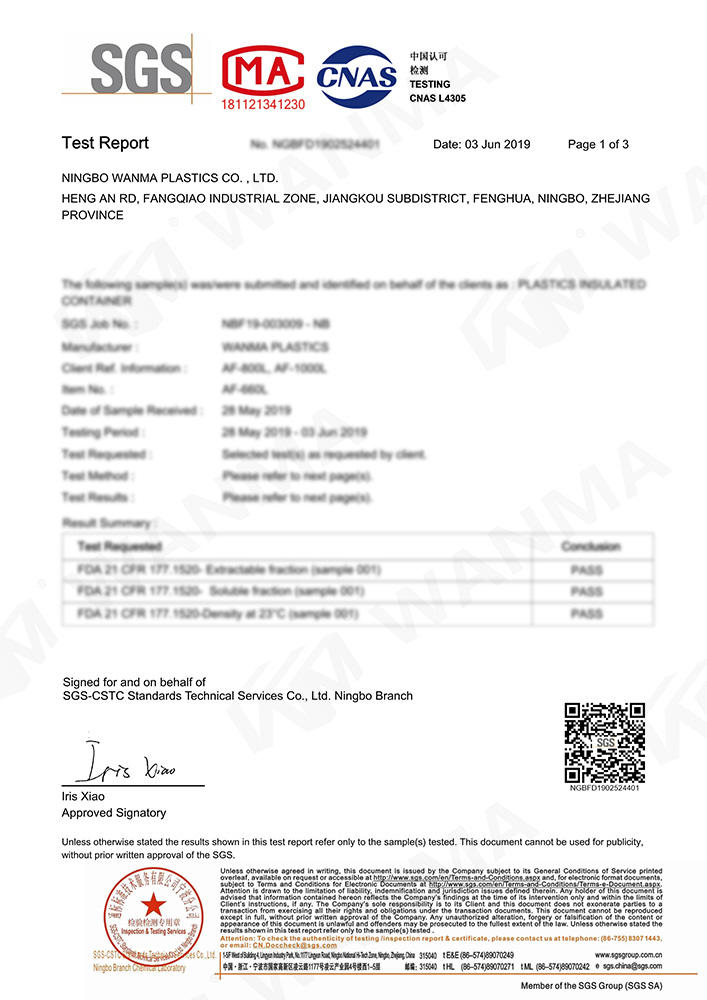

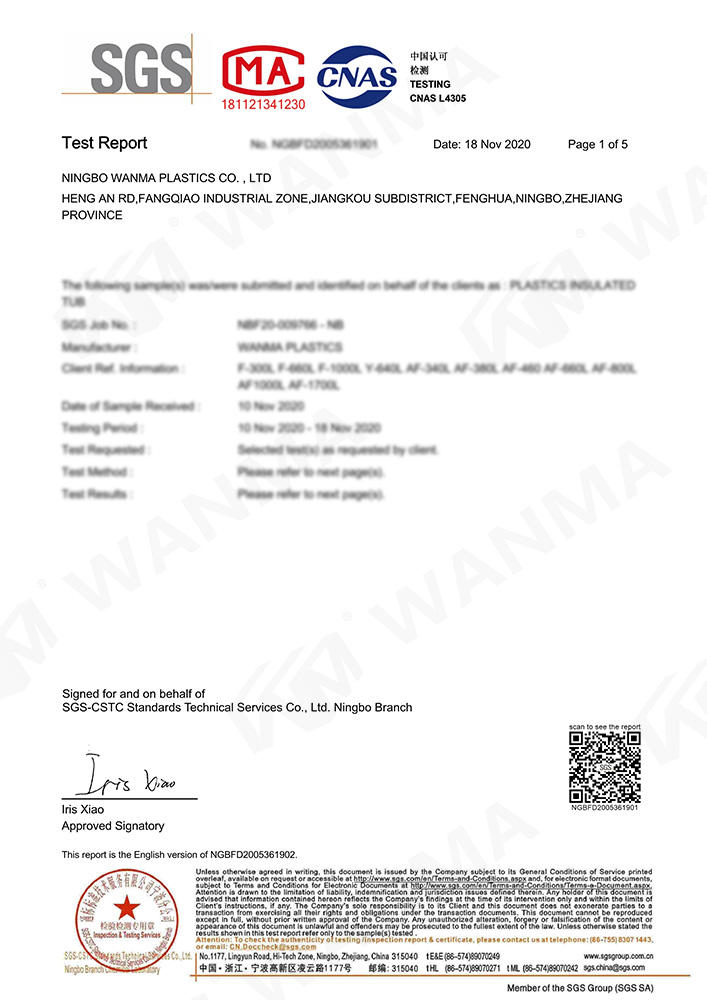

Quality and Certifications

Being an ISO-9001 certified manufacturer, we maintain manufacturing quality. Our products are made to European and international standards, and successfully pass the certification testing of CE, SGS and TUV on a regular basis.

Eu Report

FDA Report

Food Grade Report

ISO

ISO9001

Ice Cooler Container Industry Knowledge Extension

1. Ice Cooler Container: Keeping Your Drinks Cool and Fresh

In modern outdoor activities, whether it is camping, barbecue, or a beach vacation with family and friends, Ice Cooler Container has become an indispensable companion. This simple device not only keeps food and drinks cold, but also enhances the experience of the entire event. As a company that provides innovative and high-quality products, Ningbo Wanma Plastics Co., Ltd. fully understands the importance of Ice Cooler Container in every outdoor event.

The main function of Ice Cooler Container is to keep food and drinks fresh and prevent them from spoiling in a warm environment. In the hot summer, imagine how unpleasant the outdoor party will be without iced drinks and fresh food. The Ice Cooler Container is the key to solving this problem. Through its efficient insulation design, it keeps ice cubes cool for longer, ensuring that your drinks and food are kept at the ideal temperature and always fresh.

By cooperating with Ningbo Wanma Plastics Co., Ltd., customers can enjoy first-class product quality and innovative technology. We adhere to the principle of "people-oriented, integrity first", and strive to provide excellent performance and efficient cooling effect in each product to make your outdoor activities more comfortable and enjoyable.

2.Why You Need a Cooler Box for Outdoor Activities

In outdoor activities, especially in hot weather, it is crucial to keep food and drinks cold. Without an effective refrigeration device, food may spoil quickly and drinks may easily become warm, affecting the quality of the entire activity. And this is where the cooler box comes in - providing you with a convenient way to ensure that you can enjoy cool drinks and fresh food when you are out.

The design concept of the Cooler box is very simple: through efficient insulation materials and reasonable volume design, it ensures that it can maintain low temperatures for a long time. When you use these coolers, whether it is a long beach sunbathing or a camping night, it can provide the most ideal storage environment for your food and drinks. When we, Ningbo Wanma Plastics Co., Ltd., designed and manufactured the Ice Cooler Container, we fully considered how to improve its convenience and insulation effect, ensuring that you can experience the comfort of refrigeration no matter where you are.

We know that customer needs and expectations are the driving force behind our company's continuous innovation and development. We are always committed to providing customers with high-quality, innovatively designed products to help them enjoy a better experience in outdoor activities. This is also a reflection of our corporate culture of "integrity first, innovation-oriented".

3.How an Ice Cooler Container Works

The working principle of Ice Cooler Container is actually not complicated, but it is the key to its effective low temperature. These cooling containers prevent hot air from entering through double insulation layers inside and outside, thereby maintaining a low temperature environment inside. Usually, Ice Cooler Container uses thick foam or other high-efficiency insulation materials, which can effectively prevent heat transfer and keep ice cubes in the container for longer.

When you put ice cubes into the cooler box, the ice cubes will cool the stored items by directly contacting the air and the inner surface of the container. The design and sealing of the container play a vital role here. A good sealing design can reduce the loss of cold air and ensure that the low temperature environment in the refrigerator is maintained.

Ningbo Wanma Plastics Co., Ltd. pays special attention to how to maximize the insulation effect of the refrigerator while ensuring the durability and convenience of the product when developing Ice Cooler Container. Through continuous innovation and strict quality control, our Ice Cooler Containers can provide customers with longer refrigeration effects, making every outdoor activity more enjoyable.

Our company adheres to the concept of "integrity-based, innovation-driven" and knows the importance of every detail. In the production process of each cooler box, we strictly control to ensure that each product can meet the high standards of customers.

4.Choosing the Right Ice Cooler Container for Your Needs

Choosing the right Ice Cooler Container is a key step to ensure the success of your outdoor activities. There are many coolers of different sizes, materials and functions on the market. How to choose the product that suits your needs? You need to consider the usage scenario: If you plan a long trip or a multi-person camping, you may need a large-capacity cooler box, which can accommodate more food and drinks. If you are just going on a short trip or going to the park for a picnic with your family, a small and convenient Ice Cooler Container may be more in line with your needs.

In addition to capacity, the portability, durability and sealing performance of the cooler are also very important considerations. Our Ice Cooler Containers from Ningbo Wanma Plastics Co., Ltd. are designed with these needs in mind. Our products are not only easy to carry, but also well sealed and can maintain low temperatures for a long time.

We always adhere to the concept of "people-oriented, integrity first" and are committed to providing customers with high-quality products and services. Through innovation and continuous progress, Ningbo Wanma Plastics Co., Ltd. brings customers more refrigeration solutions that meet their needs. We believe that only through high-quality products and professional services can we achieve prosperity and progress with our customers.

English

English Español

Español عربى

عربى 中文简体

中文简体