STEP.1

Customer concept or design

Upload your file in the right format. You can also email us and attach your files, then a design specialist will help you get your design started.

With unrivaled experience working with Food Turnover Box we can provide you and your team to design products to suit your needs. We handle the entire process from quotation requests through to production of the finished product.

Focus on optimization of all manufacturing and assembly to reduce overall cost.

Functional product design to give your company product differentiation and competitive advantage.

Experienced in providing design solutions for part consolidation and complex assemblies.

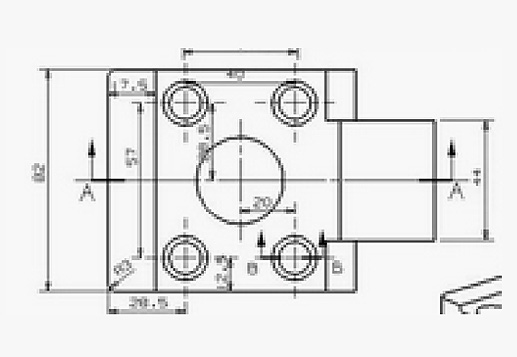

Proficient with all major CAD softwares in working with your 2D drawings and 3D models.

Our products meet international standards and are mainly exported to main countries and regions

Upload your file in the right format. You can also email us and attach your files, then a design specialist will help you get your design started.

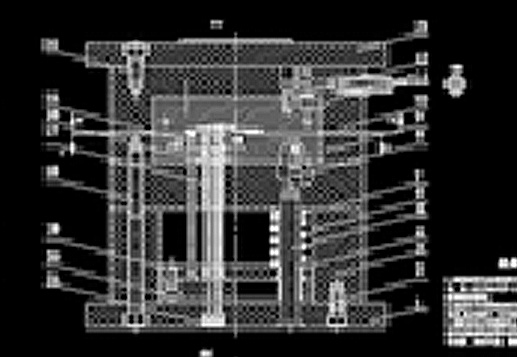

Analyze and optimize all functions, finishes, procurement...and assure tooling limitations and our capabilities.

Our engineering team will design the right deep draw tooling the first time, ensuring superior deep draw parts & on-time delivery of your new prototype.

Our rapid 3D printing is a cost-effective way to put your newest ideas to the test and give you the flexibility to create, test and refine.

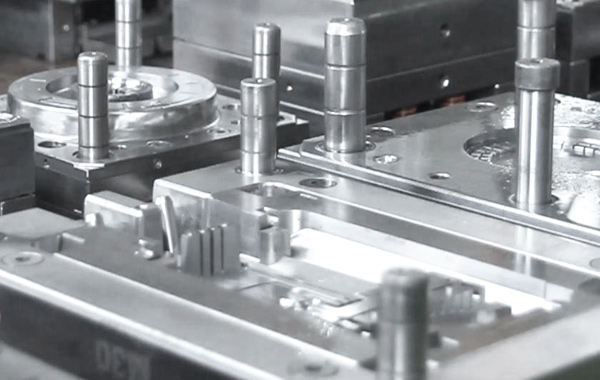

Moldings are produced in our injection factory, guaranteed to specs. We currently focus on plastic injection, but more value-added processes are available.

You'll always be able to require your individual production tracking information and get reports and graph over time.

Our highly experienced project managers will provide you with total project management across all phases of your molding project. Your WANMA manager will identify optimization along every step of the way which will result in the elimination of unnecessary costs, thereby increasing the overall value and cost-effectiveness of your project.