Technical Data

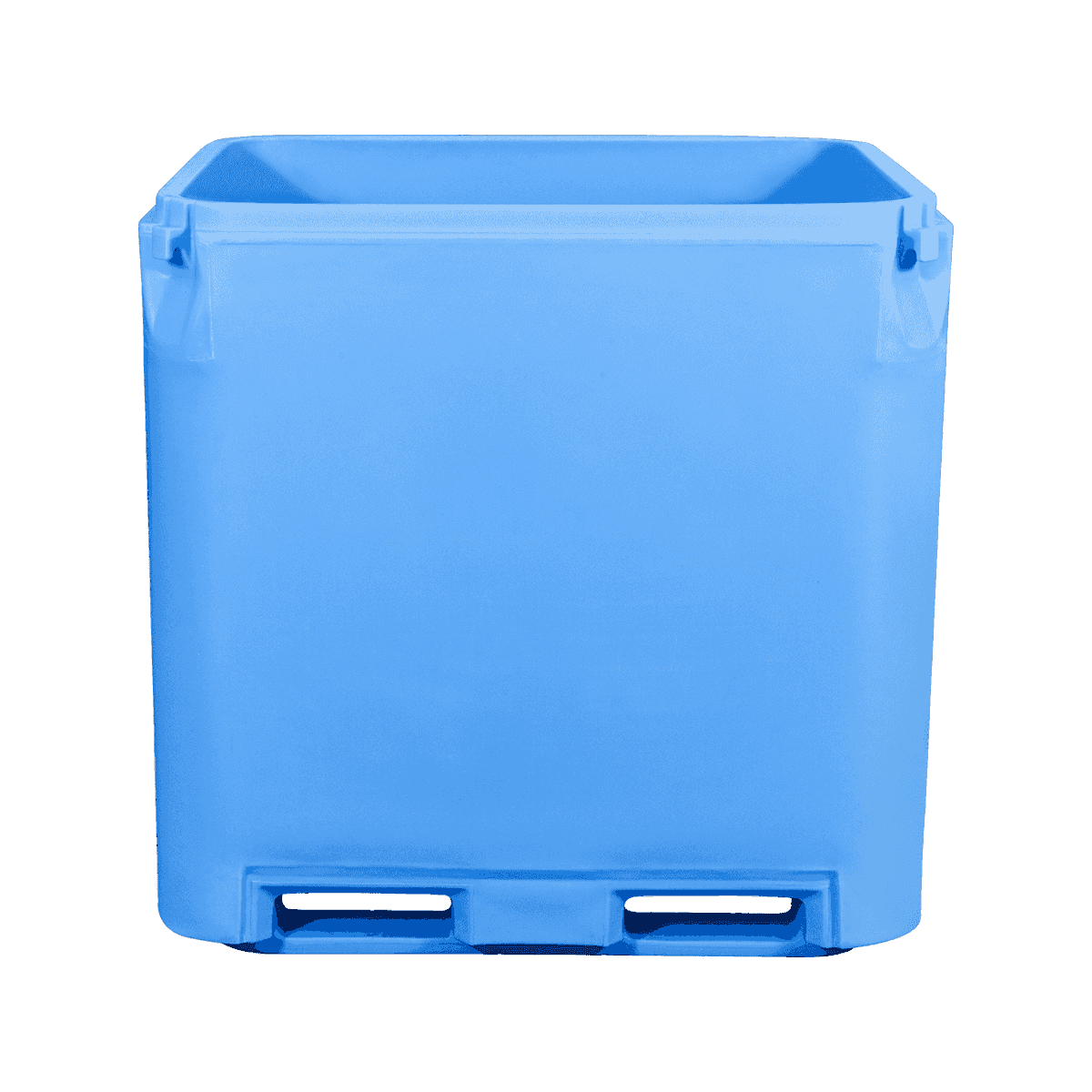

| Feature | Detail |

|---|---|

| Entry Method |

Standard Four-Way Forklift Entry |

| Base Design |

Integrated Pallet/Skid Base (Optional Runners) |

| Clearance |

Optimized Fork Tine Clearance for Safe Entry |

| Material Reinforcement |

Reinforced Plastic in Tine Entry Zones |

| Compatibility |

Works with Standard $\text{550mm}$ and $\text{685mm}$ Width Pallet Jacks |

| Load Capacity |

High Weight Tolerance for Full Liquid/Solid Loads |

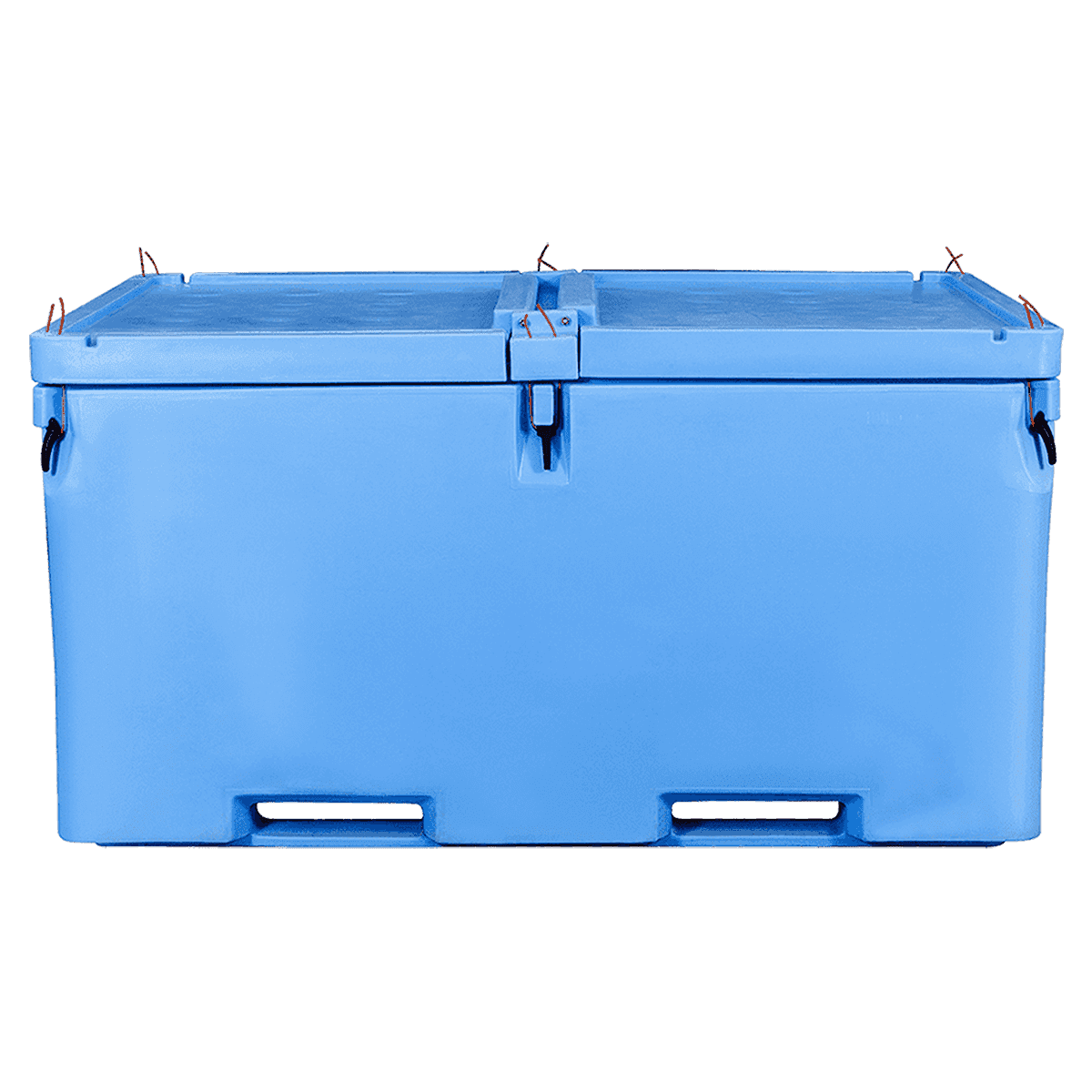

Primary Use Cases

-

Warehouse Operations: Rapid movement of cold goods between storage areas and loading docks.

-

Processing Facilities: Positioning large insulated bins containing raw or processed materials on assembly lines.

-

Cold Chain Loading: Efficiently loading and unloading refrigerated trucks and sea containers.

-

Inter-Facility Transfer: Secure transport of insulated goods over paved or semi-smooth industrial floors.

Why Choose Our Containers?

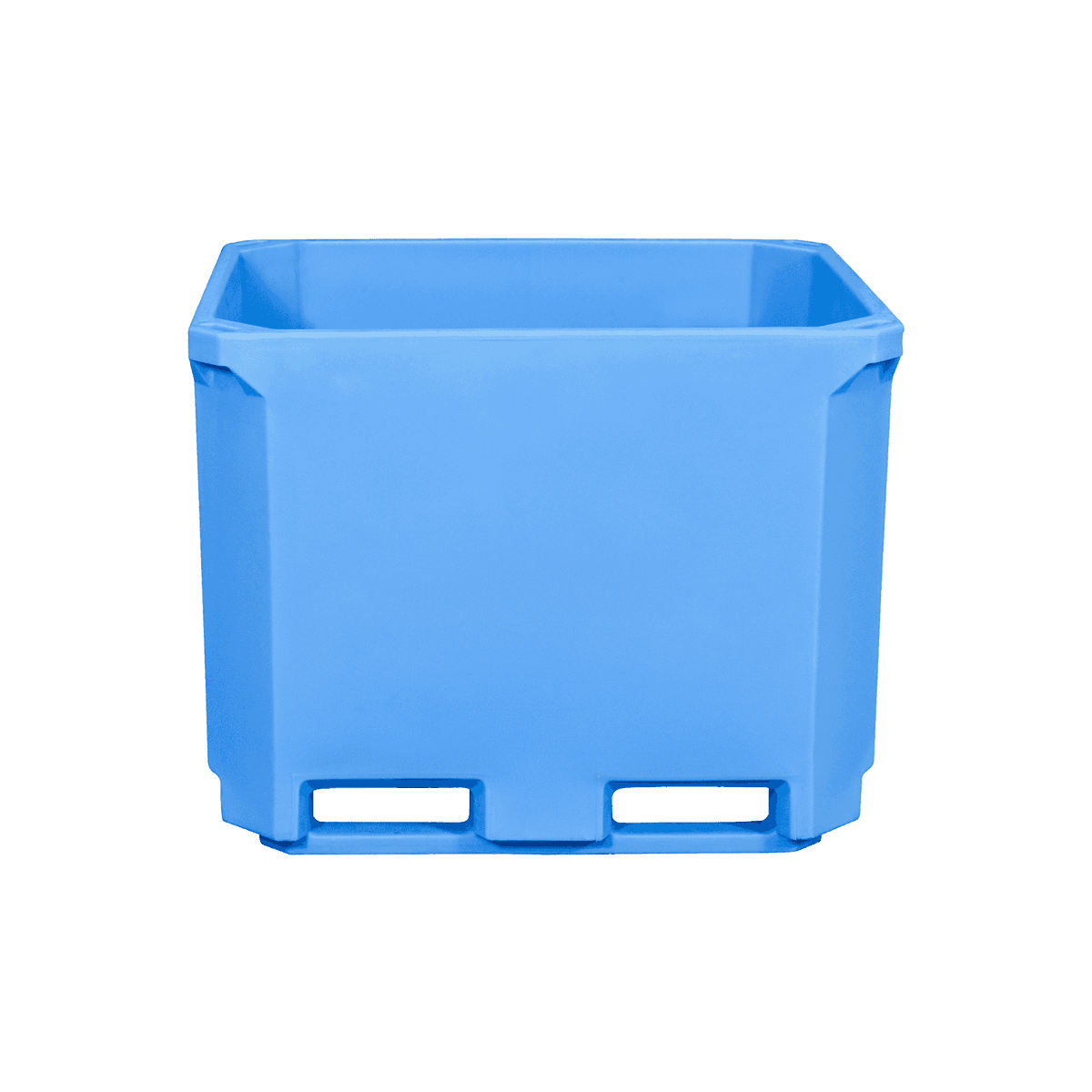

-

Efficiency and Speed: Integrated forklift access eliminates the double handling step of placing or removing goods from separate wood or plastic pallets.

-

Reduced Maintenance: Unlike wood pallets, our integrated plastic bases are impervious to water damage, splinters, or pest infestation, leading to lower maintenance costs.

-

Safety in Handling: The containers are designed to resist slippage on fork tines, improving stability and reducing the risk of accidents during lifting.

-

Structural Durability: The pallet base is structurally reinforced to withstand thousands of mechanical lifting cycles without failure.

English

English Español

Español عربى

عربى 中文简体

中文简体-4.png)

-4.png)

-2.png)