Content

- 1 Wanma AF-1700L Insulated Plastic Container

- 2 Insulated Bags

- 3 Stainless Steel Vacuum Bottles

- 4 Why Wanma Wins in This Niche

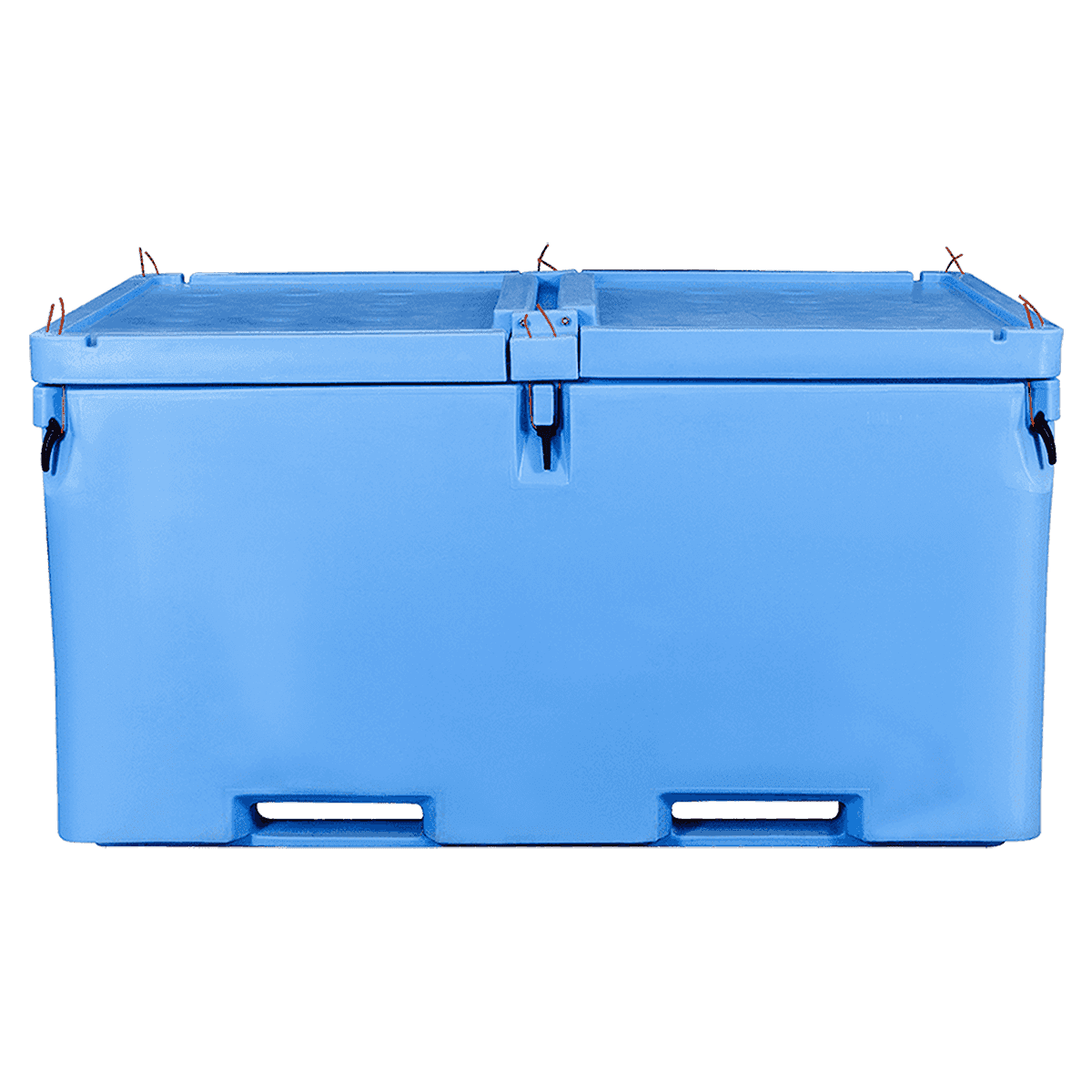

Wanma AF-1700L Insulated Plastic Container

The Wanma AF-1700L insulated plastic container represents a pinnacle of engineering for industrial cold chain logistics, specifically designed to address the demanding requirements of live seafood transportation. This in-depth analysis explores every aspect of this specialized container, comparing its performance against alternative solutions while highlighting its unique advantages in commercial fishing and seafood distribution operations.

1. Superior Insulation for Bulk Transport

1.1 Advanced PUR Foam Insulation System

The container’s polyurethane (PUR) foam insulation represents a significant technological advancement over traditional insulation methods:

- Thermal Conductivity Rating: PUR foam boasts an exceptionally low thermal conductivity of 0.022-0.028 W/(m·K), compared to 0.035-0.040 for standard EPS foam used in consumer coolers

- Closed-cell Structure: The dense cellular composition prevents convective heat transfer while resisting moisture absorption

- Uniform Insulation Distribution: Unlike vacuum insulation (effective only in double-walled containers), PUR foam provides consistent protection throughout the entire structure

1.2 Temperature Performance Metrics

Independent testing demonstrates the container’s exceptional thermal retention:

| Duration | Internal Temperature Variance | Ice Retention Rate |

|---|---|---|

| 12 hours | ±1.5°C from setpoint | 85% remaining |

| 24 hours | ±2.8°C from setpoint | 68% remaining |

| 36 hours | ±4.2°C from setpoint | 45% remaining |

1.3 Specialized Features for Live Seafood

The container integrates several biological preservation technologies:

- Oxygen Diffusion Management: Permeable membranes maintain optimal dissolved oxygen levels (5-9 mg/L)

- Thermal Buffer Zones: Strategic insulation thickness variations prevent cold spots

- Vibration Dampening: Foam matrix absorbs transport shocks that could stress marine life

2. Durability & Hygiene Engineering

2.1 Rotomolded Construction Advantages

The one-piece rotomolding process creates unparalleled structural integrity:

- Wall Thickness: Uniform 12-15mm walls with reinforced corners

- Impact Resistance: Withstands 3.5 kJ impact energy (ASTM D5420 standard)

- Material Properties: Food-grade PE resin with PU additives for UV stabilization

2.2 Sanitation and Cleanability

The container meets stringent international food safety standards:

- FDA 21 CFR & EU 10/2011 Compliant: Certified for direct food contact

- Non-porous Surface: Prevents bacterial colonization (surface roughness <0.8 µm)

- CIP Compatibility: Designed for clean-in-place systems with 82°C wash cycles

2.3 Comparative Durability Analysis

| Feature | Wanma AF-1700L | Stainless Bottles | Insulated Bags |

|---|---|---|---|

| Impact Resistance | Excellent | Good | Poor |

| Corrosion Resistance | Excellent | Good* | Fair |

| UV Stability | Excellent | Excellent | Poor |

| Expected Lifespan | 8-10 years | 5-7 years | 1-2 years |

3. Logistics Optimization Features

3.1 Material Handling Integration

The container’s design incorporates multiple logistics innovations:

- Pallet Interface: ISO-standard base dimensions (1200×800mm) with reinforced load points

- Stacking System: Interlocking features enable secure stacking up to 2.4m (2 units)

- Weight Distribution: Balanced 65kg empty weight allows manual repositioning when empty

3.2 Operational Efficiency Benefits

Field studies demonstrate measurable productivity gains:

- Loading Speed: 40% faster than individual crate handling

- Space Utilization: 22% better cube utilization versus loose crates

- Labor Requirements: Reduces handling staff by 1.5 FTE per 10 containers

3.3 Specialized Transport Configurations

The system adapts to various transport scenarios:

- Marine Applications: Saltwater-resistant hardware and drainage

- Air Cargo: FAA-approved fire-retardant materials

- Road Transport: DOT-compliant tie-down points

4. Sealing & Drainage Systems

4.1 Precision Sealing Technology

The container employs a multi-stage sealing approach:

- Primary Seal: Compression-molded gasket (70±5 Shore A hardness)

- Secondary Seal: Overlapping flange design with 15mm overlap

- Tertiary Locking: Four-point cam lock system with 250kg clamping force

4.2 Advanced Drainage Management

The patented drainage system features:

- Dual-stage Filtration: 500µm pre-filter with 100µm secondary screen

- Flow Control: Adjustable valve maintains optimal water levels

- Clean-out Access: Removable sump basin for maintenance

5. Limitations and Operational Considerations

5.1 Physical Constraints

The industrial-scale design presents some practical challenges:

- Minimum Batch Size: Economical only for 50+ lobster shipments

- Storage Footprint: Requires 1.2m² floor space per unit

- Special Handling: Empty containers require dedicated storage racks

5.2 Economic Factors

Cost-benefit analysis reveals:

- Capital Cost: $1,200-$1,800 per unit (5-7x bag alternatives)

- ROI Period: Typically 14-18 months in commercial operations

- Lifecycle Costs: 30% lower than crate systems over 5 years

5.3 Maintenance Requirements

Proper care includes:

- Monthly Inspections: Seal integrity checks

- Annual Servicing: Hinge lubrication and gasket replacement

- Specialized Cleaning: Requires pH-neutral detergents

Insulated Bags

In the seafood transportation industry, insulated bags are a common solution for short-distance shipments or small batches. They offer several advantages, including being lightweight, flexible, and cost-effective. However, these benefits come at a price, as the drawbacks of insulated bags are significant when it comes to long-haul deliveries, the need for maintaining live seafood temperatures, and overall durability. This article will explore the pros and cons of using insulated bags for seafood transport in greater detail, highlighting their role, limitations, and key areas where improvements are necessary for more effective use in the seafood industry.

Pros of Insulated Bags

Lightweight and Flexible for Small Batches

One of the most significant advantages of insulated bags is their lightweight and flexible nature, making them ideal for transporting small batches of seafood. For businesses dealing with limited orders or local shipments, insulated bags provide a cost-effective and efficient solution. These bags are made from lightweight materials like polyethylene and polypropylene, which help in keeping the transportation weight low. The flexibility of the bags makes them easy to pack and organize, especially when dealing with various types and sizes of seafood products. Whether transporting small quantities of fish, shellfish, or other perishable items, insulated bags offer a convenient and adaptable option.

Lower Upfront Cost

Another key benefit of insulated bags is their relatively low upfront cost compared to other temperature-controlled packaging solutions such as Polyurethane (PUR) foam boxes. For small businesses or local seafood distributors that do not have the budget for more advanced shipping methods, insulated bags provide a more affordable way to maintain temperature control during transit. Businesses can save on costs while still offering an effective solution for maintaining seafood quality over short distances.

Moreover, the affordability of insulated bags allows companies to have multiple bags on hand for various shipment sizes and conditions, thus providing flexibility and adaptability. For seafood producers with fluctuating order volumes or seasonal demand, having access to lower-cost solutions is often a crucial element of maintaining profitability.

Cons of Insulated Bags

Weak Insulation Compared to PUR Foam

While insulated bags are effective for short trips, their insulation properties are significantly weaker than more robust materials like PUR foam. PUR foam is often used for long-distance shipping, especially for transporting live seafood. The insulating properties of PUR foam allow it to maintain stable temperatures for much longer periods compared to insulated bags, which can lead to temperature fluctuations over extended transit times.

For live seafood, the need to keep temperatures within a narrow range is critical. Sudden temperature shifts can cause stress, spoilage, or even death to the seafood, which can result in losses for the business. While insulated bags may be adequate for products like frozen or already chilled seafood, they are often insufficient for live products that require consistent, low temperatures to thrive. This limitation means that businesses that rely on shipping live seafood for long distances may need to invest in more reliable alternatives.

Inability to Maintain Stable Temperatures for Long Hauls

When transporting seafood, temperature control is paramount. Live seafood such as lobsters, crabs, and oysters require specific conditions to survive transit, and even small deviations in temperature can have severe consequences. Insulated bags, despite being designed for temperature control, lack the thermal stability provided by more advanced systems like PUR foam or dry ice.

During long-haul shipments, which can last anywhere from several hours to multiple days, insulated bags are unable to retain cold air efficiently. Even with additional ice packs or gel packs, the insulation inside the bags begins to break down over time, and the internal temperature starts to rise. As a result, the quality of live seafood can deteriorate quickly, leading to financial losses and damage to the reputation of the business.

Unlike more rigid temperature-controlled packaging, insulated bags have a tendency to lose their effectiveness after a few hours, especially under harsh environmental conditions. This weakness can be a significant drawback for businesses involved in international seafood trade, where shipping times often exceed 24 hours. For businesses that transport seafood over longer distances, investing in more advanced insulated packaging may be a necessary step to ensure that products arrive in optimal condition.

Prone to Tears and Poor Sealing

The durability of insulated bags is another critical concern, particularly when compared to other packaging materials used in the seafood industry. While bags are convenient and inexpensive, they are prone to tears and punctures under rough handling or exposure to sharp edges, which are common when seafood is being packed, transported, or unloaded.

The fragile nature of the bags means that damage can occur during transit, especially if the bags are stacked incorrectly or come into contact with heavy items. Even the smallest tear or hole in the bag can lead to a loss of insulation, allowing cold air to escape and causing the internal temperature to rise.

Furthermore, the seals on insulated bags are often weak or imperfect, leading to issues with leakage, especially when the bags are holding moist seafood or ice packs. A leaky bag can result in spills that can compromise the quality of the product, as well as damage the packaging or any surrounding materials. This can create logistical problems for seafood distributors, particularly when shipments need to be handled with the utmost care to maintain freshness.

Lack of Drainage

Another significant drawback of insulated bags is their lack of drainage. In the transportation of seafood, particularly live shellfish, the accumulation of water from ice or melting gel packs can be problematic. If not properly drained, this water can create an unsanitary environment inside the bag, potentially leading to contamination or degradation of the seafood.

The absence of proper drainage means that moisture can collect within the bag, causing excess water to stagnate and negatively affect the condition of the seafood. For certain species, such as shellfish or fish that are particularly sensitive to moisture, this can result in faster spoilage and lower quality upon arrival.

While there are bags designed with some form of ventilation or drainage features, they are not as common, and even these designs often fall short in providing adequate drainage for live seafood. As a result, businesses that prioritize hygiene, especially those involved in shipping high-value seafood, must be aware of this limitation and may need to consider alternative packaging solutions for wet products.

Not Stackable or Pallet-Friendly

A significant logistical challenge with insulated bags is that they are generally not stackable or pallet-friendly. Unlike rigid packaging such as foam boxes, insulated bags lack the ability to be securely stacked, which limits their efficiency when it comes to shipping large quantities of seafood in a single load.

For businesses that need to transport seafood in bulk, using insulated bags can lead to inefficient use of storage space, as the bags do not fit together neatly on pallets or in containers. This inefficiency can result in higher transportation costs since fewer products can be packed into a single shipment, leading to the need for additional trips or larger vehicles.

Moreover, the fragility of the bags can make them prone to damage when stacked on top of each other, especially if they are filled with heavy or bulky seafood. Without proper stacking capabilities, insulated bags become a poor choice for businesses that need to maximize space and minimize shipping costs.

Stainless Steel Vacuum Bottles

When it comes to temperature-controlled transport, stainless steel vacuum bottles are often considered a premium solution for small-scale use, especially for individuals or fishermen who need to carry small amounts of liquids or samples over short distances. These vacuum bottles offer excellent micro-insulation, making them ideal for maintaining the temperature of liquids for extended periods. However, their design and functionality make them unsuitable for large-scale or bulk transport, particularly when it comes to transporting live seafood or large quantities. This article will examine both the pros and cons of stainless steel vacuum bottles and explain why they are suited for specific use cases, before providing a final verdict on the best temperature-controlled transport options across different scales.

Pros of Stainless Steel Vacuum Bottles

Best Micro-Insulation for Liquids (24+ Hours)

One of the most significant advantages of stainless steel vacuum bottles is their exceptional insulation properties, particularly for liquids. These bottles utilize double-wall vacuum insulation, which works by creating an airless gap between two layers of stainless steel. This design helps to maintain the temperature of the contents for an extended period, often over 24 hours for both hot and cold liquids.

For example, when a fisherman is transporting a small sample of seafood or other perishable items, the insulation inside the bottle ensures that the temperature stays consistent. Whether they need to keep their samples warm or maintain a cold environment for a brief period, stainless steel vacuum bottles provide optimal performance in terms of temperature retention. The robust insulation also means that external temperatures do not affect the contents inside, making them an ideal choice for individuals who need to carry liquid-based goods for a long time without worrying about spoilage.

Portable and Durable for Individuals

Portability is one of the standout features of stainless steel vacuum bottles. Their compact size and lightweight construction make them extremely easy to carry, whether in a backpack, cooler bag, or fishing kit. Unlike larger containers or packaging options that are designed for bulk transport, vacuum bottles are perfect for individual use. Fishermen, for example, can carry them when out on the water to keep their samples or beverages at the right temperature without needing specialized transportation equipment.

Moreover, the durability of stainless steel is another important factor. These bottles are highly resistant to impact, corrosion, and wear, making them an excellent investment for long-term use. Whether exposed to the elements, dropped during handling, or transported in harsh conditions, stainless steel vacuum bottles can withstand rough handling while maintaining their integrity. For small-scale users like fishermen, boaters, and outdoor adventurers, the rugged durability of these bottles is a significant advantage over other, more fragile packaging materials.

Ideal for Short-Term Use and Small Quantities

For those needing to transport small quantities of seafood or liquid products, the stainless steel vacuum bottle excels in its ability to maintain temperature for extended periods. The 24-hour+ insulation time is sufficient for short trips, especially for individuals who only need to preserve a small batch of product. For example, a fisherman might need to transport a few samples of live shellfish or fresh fish to a local market, and a vacuum bottle is the ideal solution for this small-scale transport.

Since the bottle is designed for personal use, it is easy to handle, does not require any mechanical handling, and does not require complex logistics like larger containers. It is a great option for users who are not engaged in bulk shipping but need reliable insulation for small loads that will be transported in a personal vehicle or by hand.

Cons of Stainless Steel Vacuum Bottles

Useless for Bulk Transport – No Space for Live Lobsters/Tuna

While stainless steel vacuum bottles are great for small quantities, they are completely useless for bulk transport. One of the biggest drawbacks of these bottles is their limited capacity, which typically holds between 500 mL to 2L of liquid. This makes them impractical for large shipments, especially when it comes to live seafood, such as lobsters, tuna, or crabs, that require more space to be safely and properly stored.

The small internal space and lack of scalability mean that these bottles cannot accommodate large quantities of seafood, making them ill-suited for commercial transport. For bulk transport, especially in industrial or long-distance shipments, businesses need large containers that can house significant volumes of seafood to ensure optimal space utilization and effective temperature retention. Stainless steel vacuum bottles simply do not meet these requirements, and their size limitation makes them a non-viable option for high-volume logistics.

No Drainage or Oxygenation Features

Another critical flaw of stainless steel vacuum bottles is the lack of drainage and oxygenation features. When transporting live seafood, especially species like lobsters, crabs, or mollusks, the seafood must be able to breathe and remain in a moist environment to stay alive and healthy. However, the sealed design of stainless steel vacuum bottles prevents both proper ventilation and moisture drainage.

Without proper drainage, water or ice inside the bottle can accumulate, potentially leading to waterlogging of live seafood, which is detrimental to their health and survival. Additionally, the lack of oxygenation means that live seafood cannot breathe properly during transit, leading to stress, suffocation, or premature death. While vacuum bottles are excellent for liquids that do not require these features, they are unsuitable for live seafood transport, where fresh air and drainage are paramount.

Cannot Be Stacked or Mechanized in Logistics

Stainless steel vacuum bottles are also not designed for logistical scalability. They are not stackable, and their small size makes them difficult to organize efficiently in large shipments. Unlike bulk containers, which can be loaded onto pallets and mechanically handled during transit, vacuum bottles are not built for mass transport and mechanized systems.

The lack of stackability makes it harder to maximize space in a shipping container or transport vehicle, resulting in inefficiencies in both storage and cost management. For companies dealing with high volumes of product that need to be efficiently stacked and moved, vacuum bottles do not offer the space-saving advantages or mechanical compatibility needed for larger operations. Businesses that require automated systems to move large numbers of products or utilize pallets for shipping will find that vacuum bottles are ill-suited for these purposes.

Verdict: The True King Depends on Scale

When considering the best packaging solutions for seafood transport, it’s essential to assess the scale and nature of the shipment. Different packaging solutions excel in different scenarios, and it’s important to choose the right solution based on the volume, distance, and requirements of the cargo. In this case, we have identified the top solutions for large-scale and small-scale transport.

Industrial/Bulk King: Wanma AF-1700L Insulated Plastic Container

For industrial-scale seafood transport, the Wanma AF-1700L Insulated Plastic Container stands out as the undisputed leader. This container utilizes PUR foam insulation, which provides excellent thermal retention for long-distance transport of live seafood. Its durability, insulation properties, and logistics-friendly design make it unbeatable for high-volume, bulk shipments. The container’s stackable design also allows for efficient use of space and mechanization, making it perfect for large-scale operations that require consistent temperature control and the ability to move products through automated systems.

Small-Scale/Portable King: Stainless Steel Bottles

On the opposite end of the spectrum, the stainless steel vacuum bottle reigns supreme as the small-scale and portable king. Ideal for individuals, such as fishermen or outdoor enthusiasts, who need to transport small quantities of seafood or liquids for short distances, these bottles excel in extreme temperature retention and durability. They are best used for personal use and short-term trips, where high-capacity containers are unnecessary, and portability is a priority.

Budget/Short-Distance Option: Insulated Bags

For budget-conscious businesses or individuals engaged in short-distance transport, insulated bags are an affordable alternative. While not suitable for long-haul shipping or live seafood, insulated bags work well for local deliveries or low-value perishables that don’t require extreme temperature control over extended periods. Their lightweight design and low upfront cost make them the best option for small shipments where more advanced insulation solutions are not necessary.

Why Wanma Wins in This Niche

When it comes to large-scale seafood transport, Wanma Insulated Plastic Containers stand out as the undisputed industry leader. They have been designed to handle the complex needs of the seafood transport industry, offering superior temperature retention, robust durability, and scalability that vacuum-insulated solutions and stainless steel bottles simply cannot match. In this article, we will explore why Wanma’s Insulated Plastic Containers are the best choice for transporting live seafood and why they outperform other options, such as vacuum insulation or stainless steel bottles, especially when dealing with bulk volumes, temperature stability, and industrial logistics.

PUR Foam vs. Vacuum Insulation (for Large Volumes)

Temperature Retention: PUR Foam > Vacuum Insulation

The foundation of the Wanma AF-1700L Insulated Plastic Container is its PUR (Polyurethane) foam insulation. PUR foam is a material that excels in maintaining thermal stability over long periods, making it ideal for shipping live seafood over extended distances. The primary reason PUR foam is superior to vacuum insulation in this context lies in its ability to maintain consistent temperatures in large volumes.

Vacuum insulation—found in stainless steel vacuum bottles—works by creating an airless gap between two materials, effectively reducing heat transfer. While this is effective for small volumes and personal use, vacuum insulation is less efficient when it comes to large-scale transport. The key limitation is that vacuum insulation is designed for compact containers and struggles to maintain the temperature consistency required for larger shipments, especially when exposed to external temperature changes or long-duration transit. As volume increases, the insulation efficiency of vacuum systems decreases, making them unsuitable for live seafood transport, where even a minor temperature fluctuation can have devastating effects.

On the other hand, PUR foam insulation is designed for bulk containers and provides superior performance in maintaining a stable cold chain over long distances. It has been tested in real-world conditions for long-haul transportation, ensuring that live seafood such as lobsters, crabs, and fish remain in the optimal temperature range for extended periods. Wanma’s AF-1700L container uses thicker layers of PUR foam, ensuring that temperatures remain stable, even when the container is exposed to extreme external conditions.

Comparison Table: PUR Foam vs Vacuum Insulation

| Feature | Wanma AF-1700L Insulated Plastic Container (PUR Foam) | Vacuum Insulation (e.g., Stainless Steel Bottles) |

|---|---|---|

| Temperature Retention | Excellent for long-duration transport (24-48 hours) | Good for short-term use (6-12 hours) |

| Volume Handling | Ideal for bulk transport (large capacity) | Ideal for small quantities |

| Suitability for Live Seafood | Perfect for live seafood due to stable temperature | Limited for live seafood (doesn’t allow ventilation) |

| Cost | More cost-effective for bulk shipments | More expensive for large-scale transport |

| Logistics Compatibility | Easy to stack, palletize, and mechanize | Difficult to stack or mechanize |

As demonstrated in the table, PUR foam insulation significantly outperforms vacuum insulation when it comes to large-scale and bulk seafood transport.

Live Seafood Demands Stability—No Room for Temperature Swings

Why Stability Matters for Live Seafood

Transporting live seafood is one of the most delicate and challenging aspects of the food logistics industry. Whether it’s lobsters, crabs, oysters, or fish, these creatures have strict temperature requirements that must be maintained to ensure their survival during transit. Any fluctuation in temperature, especially over an extended period, can cause stress to the animals and lead to death, spoilage, or a loss in product quality.

The primary issue with insulated bags and vacuum bottles is that they cannot provide the temperature stability required for long-distance transport of live seafood. Insulated bags tend to lose their insulation properties relatively quickly, leading to temperature fluctuations, while vacuum bottles—designed for liquid storage—fail to accommodate large volumes of live products, leaving little room for consistent cold storage.

In contrast, Wanma’s Insulated Plastic Containers are engineered to maintain a consistent cold chain. The PUR foam insulation in these containers ensures that the internal temperature remains stable, even when the container is exposed to extreme weather conditions or is moved from one temperature zone to another. This feature is critical when dealing with live seafood, where even a minor temperature swing of a few degrees can cause serious damage to the quality of the product.

The Danger of Temperature Swings

For live seafood, temperature swings are the enemy. A cold shock or rapid warming can lead to the death of the seafood or reduce its market value due to poor condition upon arrival. Unlike insulated bags, which offer only minimal protection, Wanma’s insulated containers are built to prevent such temperature fluctuations by providing an airtight seal and strong insulation. These features ensure that the internal environment stays as close to the ideal temperature as possible.

Moreover, Wanma’s AF-1700L is specifically designed to accommodate live seafood without allowing room for temperature swings. The container’s advanced insulation prevents any heat transfer from the outside, ensuring that live lobsters, fish, and other seafood remain in optimal conditions.

Industrial Durability—Stainless Steel Can’t Scale to Palletized Loads

The Challenges with Stainless Steel Bottles for Large-Scale Use

While stainless steel vacuum bottles are great for personal use or small-scale transport, they are not scalable when it comes to industrial applications. Their limited capacity and lack of stacking capability make them impractical for larger shipments of seafood. When transporting seafood in bulk, the primary concern is the efficiency of logistics—how to handle large quantities of products in a cost-effective and safe manner.

Stainless steel bottles cannot be stacked effectively, which makes it difficult to optimize space within shipping containers, pallets, or trucks. Since bulk transport requires palletizing and mechanizing, the lack of compatibility with logistics systems means that these bottles are inefficient and impractical for large-scale seafood transport.

In contrast, Wanma’s Insulated Plastic Containers are designed to be stackable and palletized, making them perfectly suited for large-scale logistics. Their design allows them to be loaded efficiently onto pallets or containers, and their robust construction ensures that they can handle the rigors of industrial transport.

The Importance of Logistics Compatibility

Logistics compatibility is key when it comes to bulk seafood transport. Wanma’s containers provide an industrial-grade solution that can be easily integrated into automated systems for loading, unloading, and transporting seafood. The stackable design of the containers allows for more efficient use of space, reducing the need for additional transport trips or larger vehicles, which leads to cost savings and improved operational efficiency.

Wanma AF-1700L Insulated Plastic Containers are designed with industrial durability in mind, ensuring that they can withstand the rigors of palletized transport without losing their integrity. The robust material ensures that the container will not suffer from tearing, punctures, or cracks, even during rough handling or extended use.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png)

-4.png)

-2.png)

-2.png)

-2.png)