Content

When it comes to transporting temperature-sensitive goods, businesses are increasingly turning to Insulated Pallet Containers (IPCs) rather than traditional packaging methods. To help you understand the differences between these two packaging solutions.

1. Temperature Control

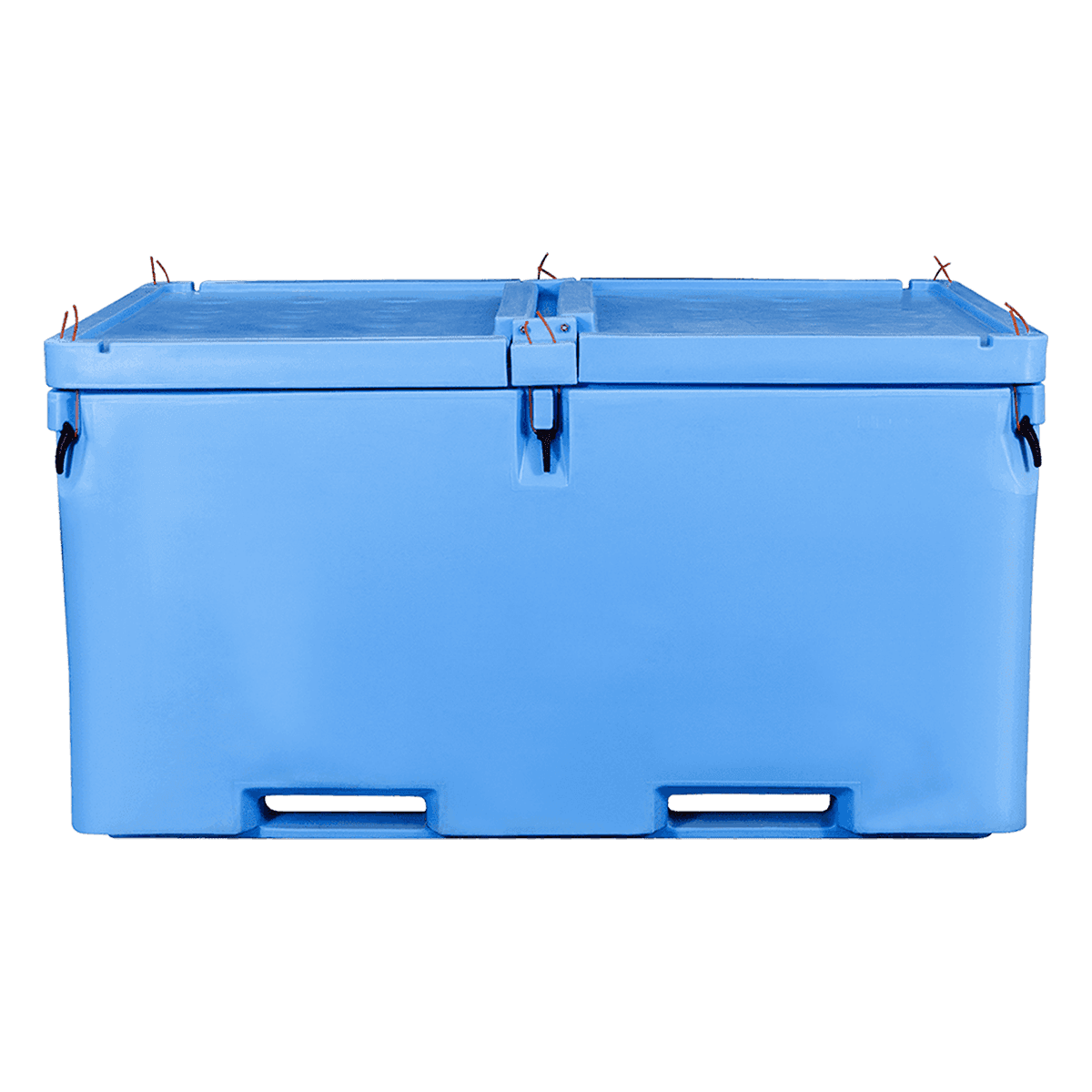

- Insulated Pallet Containers: IPCs are specifically designed to maintain a stable internal temperature, which is crucial for transporting perishable items like food, pharmaceuticals, or chemicals. These containers are made with high-performance insulation materials (such as polyurethane foam and polystyrene) that effectively block external temperature influences. IPCs create a controlled environment that prevents temperature fluctuations, ensuring that the products remain at the required temperature. Even during long-distance shipping, IPCs can maintain either cold or hot conditions for extended periods.

- Traditional Packaging: Traditional packaging methods, such as cardboard boxes or plastic crates, usually do not offer sufficient insulation. While ice packs or gel packs may be used to assist in temperature control, they often cannot maintain stable temperatures over long periods. As time passes, the effectiveness of cooling elements such as ice packs diminishes, making them less reliable for longer shipments.

2. Cost Efficiency

- Insulated Pallet Containers: While the initial cost of IPCs is higher than traditional packaging, they offer significant long-term savings. First, IPCs are highly durable and reusable, reducing the need for disposable packaging materials. Second, using IPCs decreases the need for additional temperature control measures like dry ice or refrigerated trucks, ultimately reducing shipping costs. Furthermore, by maintaining a stable temperature throughout the journey, IPCs help prevent product losses due to temperature-related issues, saving even more money.

- Traditional Packaging: Traditional packaging options are typically less expensive initially, but over time, the costs can add up. Many businesses rely on disposable materials like cardboard and ice packs, which increase ongoing expenses. In addition, if temperature control fails during transport, the resulting product damage or returns can add extra costs.

3. Durability and Reusability

- Insulated Pallet Containers: IPCs are built for durability and designed to withstand multiple uses. They can handle rough handling, varying weather conditions, and repeated transport cycles. The robust construction of IPCs ensures that their insulating properties remain effective over time. Their long lifespan makes them a cost-effective choice, especially when compared to one-time-use packaging materials.

- Traditional Packaging: In contrast, traditional packaging materials like cardboard boxes or plastic crates are not as durable. Cardboard is easily damaged by moisture, pressure, or friction, while plastic crates, though more durable, still don’t offer the same level of thermal protection as IPCs. Most traditional packaging is not designed for reuse and will deteriorate after a few uses, resulting in more waste and added costs.

4. Sustainability

- Insulated Pallet Containers: Many IPCs are made from eco-friendly, recyclable materials that not only provide excellent insulation but also help reduce environmental impact. Their reusability means fewer materials need to be produced and discarded, reducing overall waste. As more companies recognize the importance of sustainable practices, using IPCs can enhance a brand’s reputation for being environmentally responsible.

- Traditional Packaging: Traditional packaging often involves single-use materials like cardboard, foam plastic, and plastic wrap, which can contribute to significant waste. While some of these materials can be recycled, they still generate more waste compared to reusable IPCs. Additionally, the production of traditional packaging materials usually requires more resources and energy, increasing the carbon footprint.

5. Efficiency in Handling and Transport

- Insulated Pallet Containers: IPCs are designed to be easy to handle and transport. They are built to fit standard pallet sizes, allowing for efficient stacking, loading, and unloading. The uniform size and sturdy structure of IPCs also make them compatible with automated storage and transport systems, which enhances handling efficiency.

- Traditional Packaging: Traditional packaging, on the other hand, may vary in size and shape, making it harder to stack, store, and handle efficiently. For example, multiple smaller boxes may not stack as neatly as a single, large insulated container. Furthermore, traditional packaging often requires more manual labor for handling and can’t be as easily integrated into automated systems.

6. Temperature Stability Over Time

- Insulated Pallet Containers: IPCs are designed to maintain temperature stability over extended periods, making them ideal for long-haul shipments. Depending on the materials and design, IPCs can keep internal temperatures stable for 24 hours or more, ensuring that the products remain within the required temperature range for the entire journey.

- Traditional Packaging: Traditional packaging typically cannot maintain temperature stability for long durations. Even with the use of ice packs or dry ice, the temperature control effectiveness diminishes as time goes on. For products that require long-term temperature stability, traditional packaging is often insufficient.

7. Customizability and Versatility

- Insulated Pallet Containers: IPCs are highly customizable, allowing businesses to choose the size, shape, and insulation requirements that suit their specific needs. Some IPCs even come with built-in temperature monitoring systems to ensure that products remain within the desired temperature range. This customization makes them versatile for various shipping needs.

- Traditional Packaging: While traditional packaging can be customized in terms of size, it typically lacks flexibility in temperature control. Most traditional packaging cannot provide the same precise temperature regulation as IPCs, limiting their suitability for products that require strict temperature control.

| Feature | Insulated Pallet Containers (IPCs) | Traditional Packaging |

|---|---|---|

| Temperature Control | Efficient design that maintains stable temperatures over long periods | Limited temperature control, easily influenced by external factors |

| Cost Efficiency | Higher initial cost, but low long-term cost with durability and reusability | Lower upfront cost, but higher ongoing temperature control costs |

| Durability and Reusability | Durable, reusable, and designed for multiple shipping cycles | Less durable, often single-use, leading to more waste |

| Sustainability | Made from recyclable, eco-friendly materials, reducing waste | Involves single-use materials, contributing to waste and carbon footprint |

| Handling and Transport Efficiency | Easy to stack and handle, compatible with automated systems | Can be difficult to stack and handle efficiently |

| Long-Term Temperature Stability | Maintains temperature stability for extended periods | Temperature control diminishes over time, unsuitable for long-haul shipments |

| Customizability and Versatility | Highly customizable with temperature monitoring options | Customizable size but lacks flexibility in temperature regulation |

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png)

-4.png)

-2.png)

-2.png)

-2.png)