Product Category:

- All products

- Food use insulated plastic containers

- Seafood Industrial Use Plastic Containers

- Meat/Poultry Industrial Use Plastic Containers

- Logistics And Cold-Chain Containers

- Workshop And Warehouse Use Cold-Chain Containers

- Long Distance Live Fish Transportation Containers

- Live Seafood Farming & Transportation Tanks

- Outdoor leisure use cooler box

- Ice Cooler Container

- Ice Cooler Box

- Boats and docks use containers

- Vessels And Dock Use Ice Box

- Extra large size boats use containers

Product:

We Can Save Cost And Create Value For You

Our Products

Live Seafood Farming & Transportation Tanks Manufacturers

-

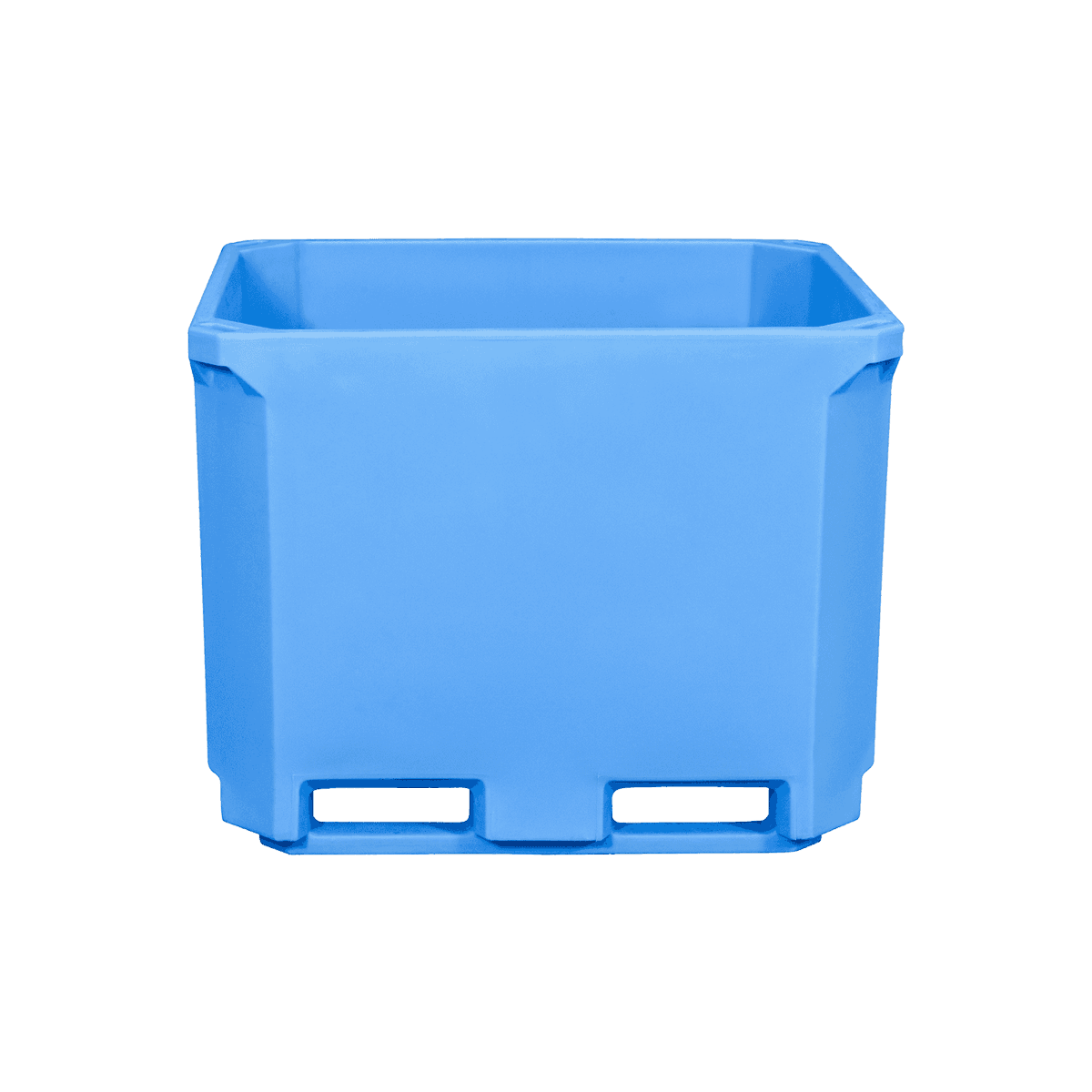

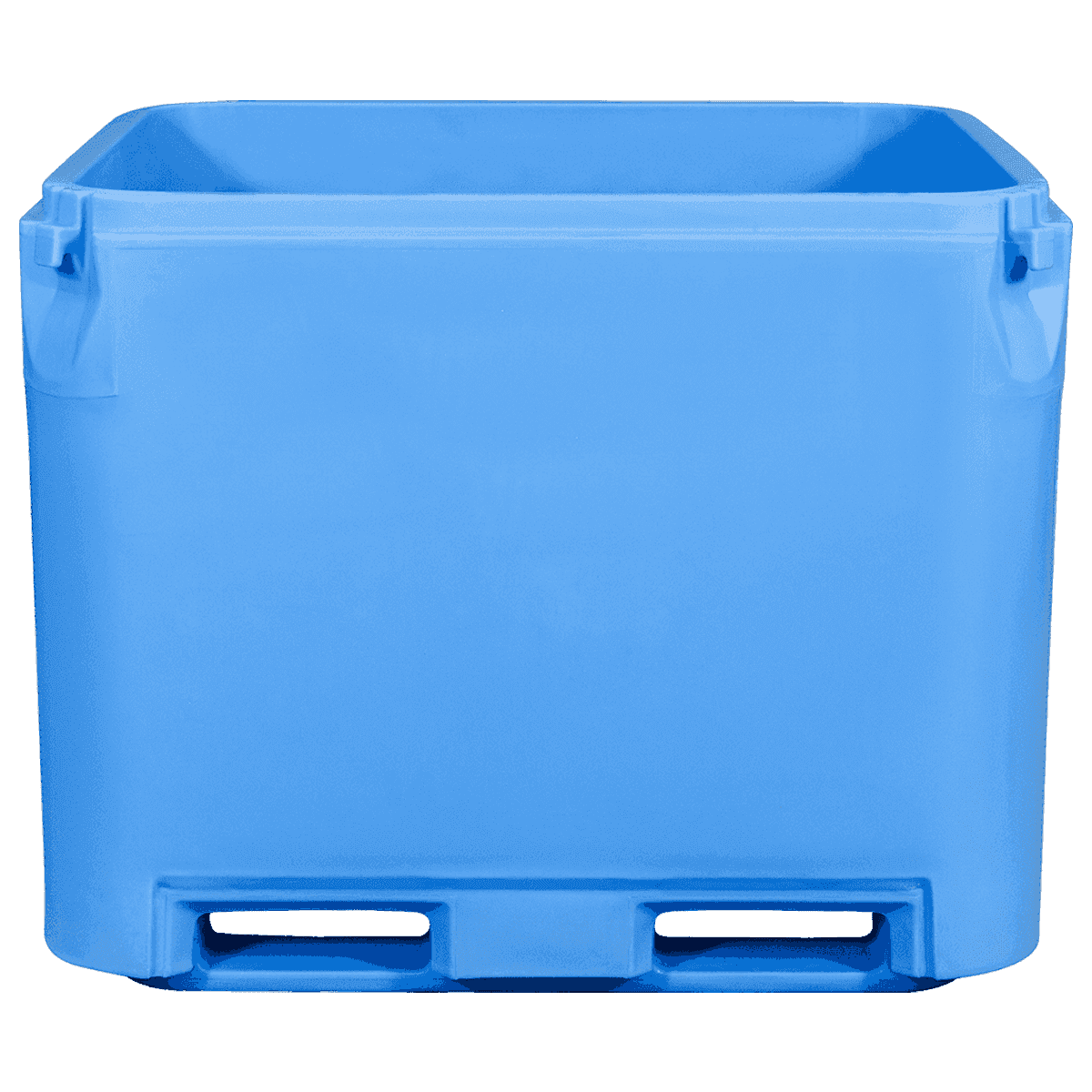

AF-380L Live Seafood Transportation Tanks

AF-380L

-

AF-800L Live Seafood Transportation Tanks

AF-800L

-

-2.png?imageView2/2/format/jp2)

X-70L Live Seafood Transportation Tanks

X-70L

-

-2.png?imageView2/2/format/jp2)

X-120L Live Seafood Transportation Tanks

X-120L

-

X-200L Short-distance Live Seafood Transportation Tanks

X-200L

since 2008

Ningbo Wanma Plastics Co.,Ltd.

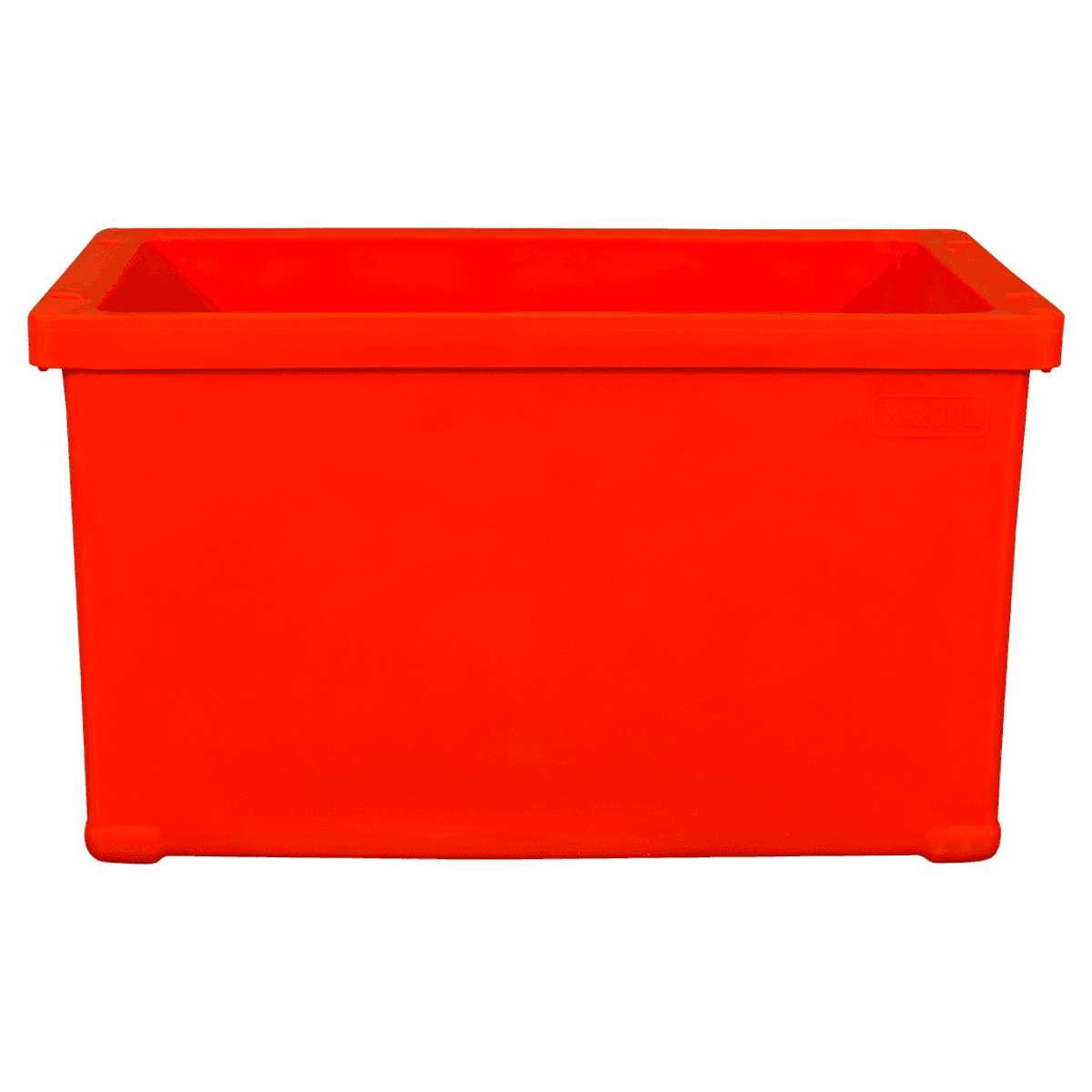

Ningbo Wanma Plastics Co., Ltd is professional China Live Seafood Farming & Transportation Tanks Manufacturers and OEM Live Seafood Farming & Transportation Tanks Company, we offer wholesale Live Seafood Farming & Transportation Tanks for sale at factory price.

Established in 2008, our company is an enterprise led by a young and creative team. We have been focusing on the design, manufacture and research and development of Live Seafood Farming & Transportation Tanks products for more than ten years. We have excellent and unique technology in the field of one-piece seamless molding of double-wall containers, such as PU filling for thermal insulation barrels and sandwich structure products. All of our Live Seafood Farming & Transportation Tanks products comply with national food hygiene standards and are widely used to fully meet the storage turnover needs of various usage scenarios.

We welcome all inquiries from all over the world with warm greetings. High quality is our cornerstone, innovation is our blood. We believe we can provide better Live Seafood Farming & Transportation Tanks products with our professional team and advanced equipment. We frankly look forward to working with you in the future.

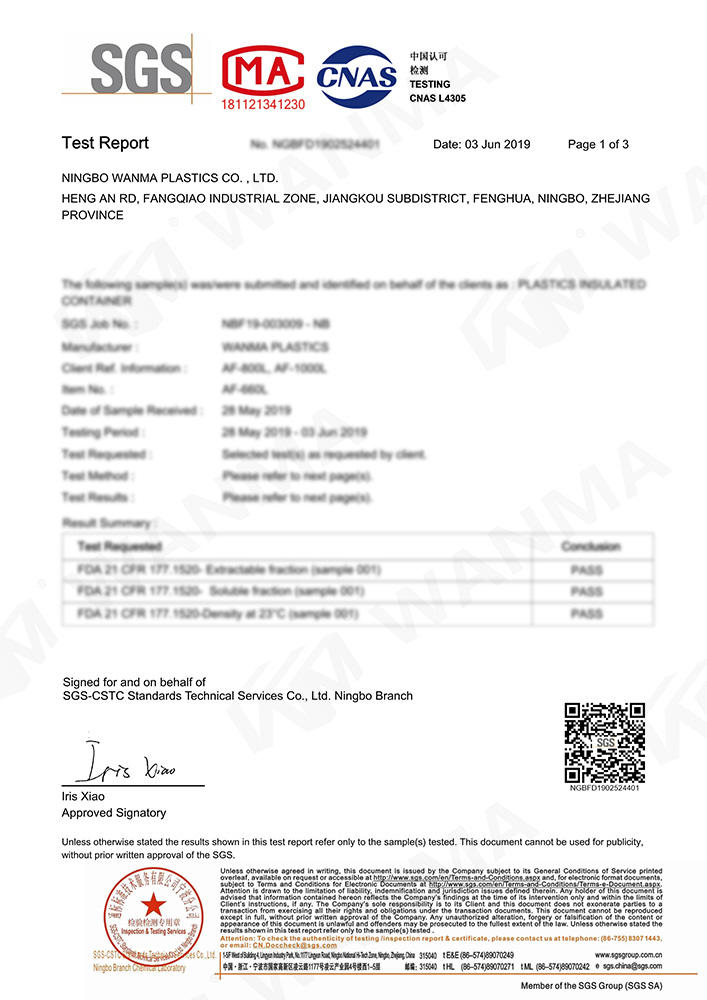

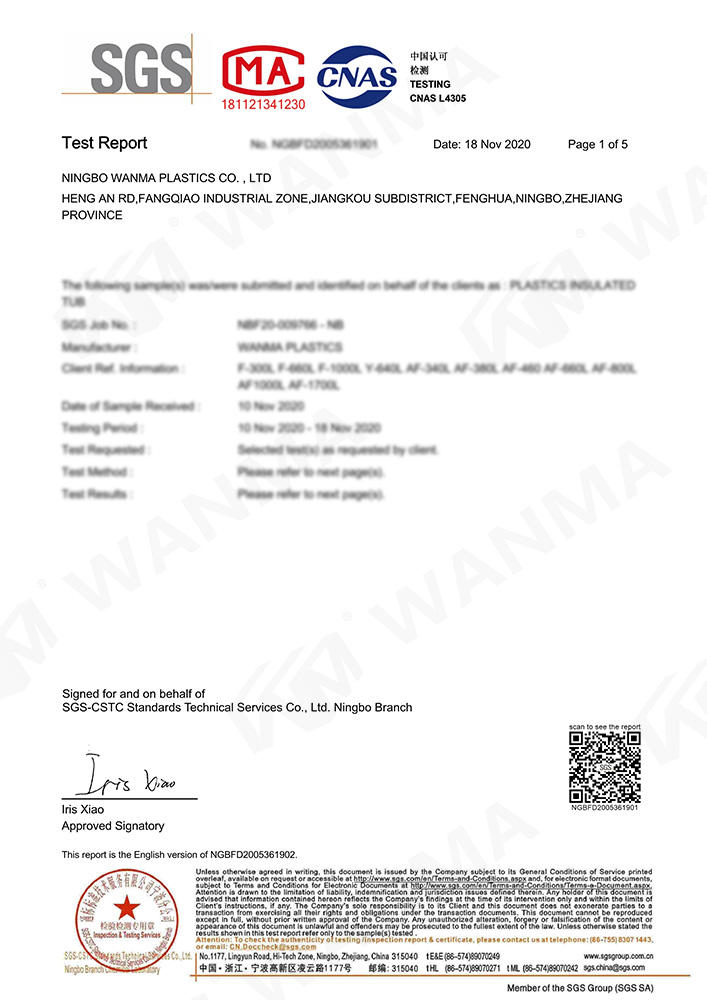

Quality and Certifications

Being an ISO-9001 certified manufacturer, we maintain manufacturing quality. Our products are made to European and international standards, and successfully pass the certification testing of CE, SGS and TUV on a regular basis.

Eu Report

FDA Report

Food Grade Report

ISO

ISO9001

English

English Español

Español عربى

عربى 中文简体

中文简体